【New Product】High Speed Radial Lead Component Insertion Machine RL133

Panasonic's mounting solutions

Our Vision

Focusing on the 5Ms (huMan, Machine, Material, Method, Measurement), which are the variable elements of the workplace, we propose an “Autonomous Factory”.

Total Solution

Introduce total solutions that “connect” equipment with each other, centered on mounting machines and printers that are used by many customers globally.

Fukuoka Technical Center

Our equipment and our partner's inspection and reflow machines are also deployed to reproduce your SMT line in the center. We accept requests for demonstrations as well as proof testing.

Operation & Maintainance

Panasonic provides reliable lifetime product support to customers ranging from installation to replacement.

Featured Contents

New Content

Solution

Support for various PCBs and production formats

As PCBs become more diverse, each industry demands a variety of component mounting needs, such as thin and large PCBs, and small component and high-density mounting.Panasonic offers solutions that support various PCBs, as well as solutions that achieve high quality and productivity.

New Product

High Speed Radial Lead Component Insertion Machine

RL133

Compatible with large component support and high-speed insertion of 0.14 seconds/component and adopting exclusive system solution for AI machines.

New Content

Solution

Respond to Automation and Manpower Saving

Automation solutions for our printing and mounting machines. These solutions help reduce labor, improve stability, and improve productivity at production sites, thereby helping to solve problems at the sites.

Updated Content

Screen Printer

NPM-GP/L

Optimizes the screen printing process. Equipped with automation functions, also capable of high-accuracy screen printing.

New Content

Solution

Respond to Parts Diversification

We provides customers with optimal solutions for their diverse parts mounting needs, including small, large, and odd-shaped parts.

Updated Content

Modular Placement Machine

NPM-GH

This edge device achieves industry-leading productivity and mounting quality for Autonomous Factory. Proposes control of irregularities in the 5Ms and elimination of skill-dependent work.

New Product

Modular Placement Machine

NPM-GW

The basic performance has been improved by renewing the core units, such as the placement head and recognition camera. It now supports a wide range of components and PCBs.

New Content

Respond to High Quality Requirements

We will introduce various functions of our mounting and printing machines and various solutions that realize high-quality by combining them with software.

Mounting MES Software

PanaCIM-EE Gen2

Support is provided for improvement in QCD in each task related to mounting, through centralized management of the entire mounting floor.

Integrated Line Management System

iLNB

Optimization of the entire production line by “connecting" Panasonic machines, non-Panasonic machines, and higher-level systems.

Products

High-speed dual/single-lane machines

The latest G series mounting machines and the market-proven NPM series realize automation/manpower saving on the SMT floor, higher line throughput, improved quality, and cost reduction.

Medium-speed single-lane machines

Versatility and compatibility with a variety of production types. Ideal for one-machine solutions.

Screen Printers

In addition to high-quality printing, many automated functions are available. Customers can choose the screen printer that best suits their application.

Insertion Machines

Our lineup can accommodate various types of insertion parts, from large parts to odd-shaped parts.

Software

Mounting Floor Integrated Management

Software for managing mounting lines and mounting floors

We contribute to the maximization of OEE by managing Panasonic's electronic component mounting systems across the entire line and reflecting them in production planning.

Electronic materials

Optimal adhesives for the printing method for microchip components, low-temperature curing adhesives for SMD flow mounting, self-alignment adhesives, and corner adhesives for reinforcing BGA/CSP.

Case Studies

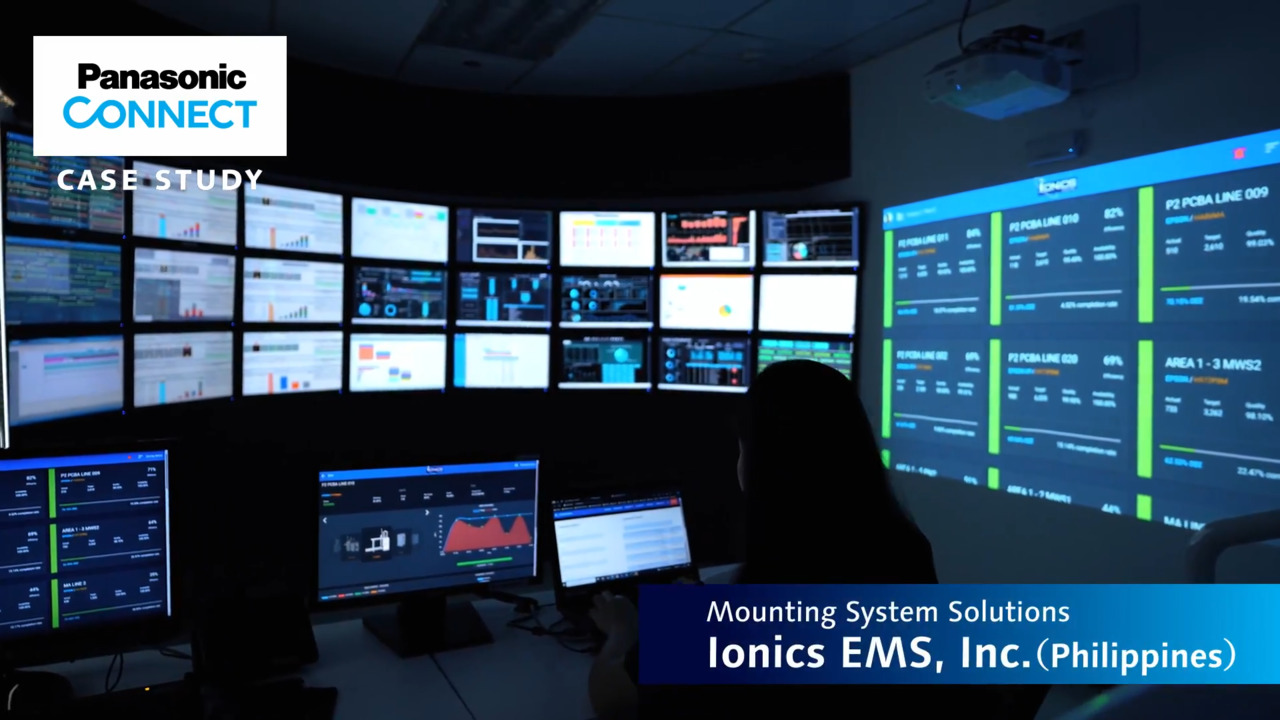

Realizing the Vision of Smart Factory (Ionics)

Ionics, a leading Philippine's EMS company, has drastically improved production efficiency by switching to Panasonic's latest machines and software. We also introduce our efforts to realize smart factories.

Smart Manufacturing to follow various changes (Shimane Fujitsu)

High-mix low-volume production to meet the diverse needs of customers. Here are examples of improvements over 30 years that have greatly improved quality, cost, and production efficiency, with automation as the main focus.

Manpower Saving SMT line (Alps Alpine)

Here are examples of high-quality software implementation and labor saving. They successfully reduced production planning time in complicated high-mix low-volume production.

Solutions

Search by problems/solutions

Here are various proposals for your manufacturing site and needs.

Factory Automation

We propose solutions for the mounting, assembly, inspection, and packing processes.

Support

Operation & Maintenance

Panasonic provides reliable lifetime product support to customers ranging from installation to replacement.

Technical Center

Customers can experience actual circuit board manufacturing using their own components and materials.

Global network

Our solid network delivers high-quality and uniform service to customers around the world regardless of time and region.

Membership Website P-Web

This is a membership website for customers of electronic component mounting systems, semiconductor-related systems, and FPD-related systems.

Line simulation

Takt simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components.

Exhibition and Seminar Information

Information on current seminars and exhibitions is posted here. Information on past seminars and exhibitions is also available.

Video Library

You can see a list of product and business introduction videos.

News

-

1 December 2025

Information

-

19 October 2023

Information

-

17 October 2023

Information

-

17 October 2023

Information

-

17 October 2023

Information

-

17 October 2023

Information

-

03 July 2023

Information

-

17 April 2023

Information

Released our English Website.

Contact

We are here to help! Contact us if you have an inquiry or question.