Auto Setting Feeder

Overview

New feeder that greatly reduces working time by automating parts supply work in the SMT process

- Automates the process of setting new tape parts, reduces approximately 60 seconds including pre-processing.(Current feeder ITF: approximately 90 seconds → Auto Setting Feeder ASF: approximately 30 seconds)

- Realized automatic loading of next parts by optional Loading Unit

(Eliminates splicing work, and saves its work time)

- Dramatically eliminates the short time breakdown caused by tape supply part

- Supports 8~104 mm width tape parts (Paper, Emboss)

- New ASF + its new cart can be attached to the current Panasonic equipment (NPM series) = Retrofit policy

Features of Auto Setting Feeder

Supports 8~104 mm width tape parts (Paper, Emboss)

Skillless auto setting and auto loading

How to attach and remove the Auto Setting Feeder

Easy installation by inserting the feeder to the depth, and easy removal by simply pulling the lever

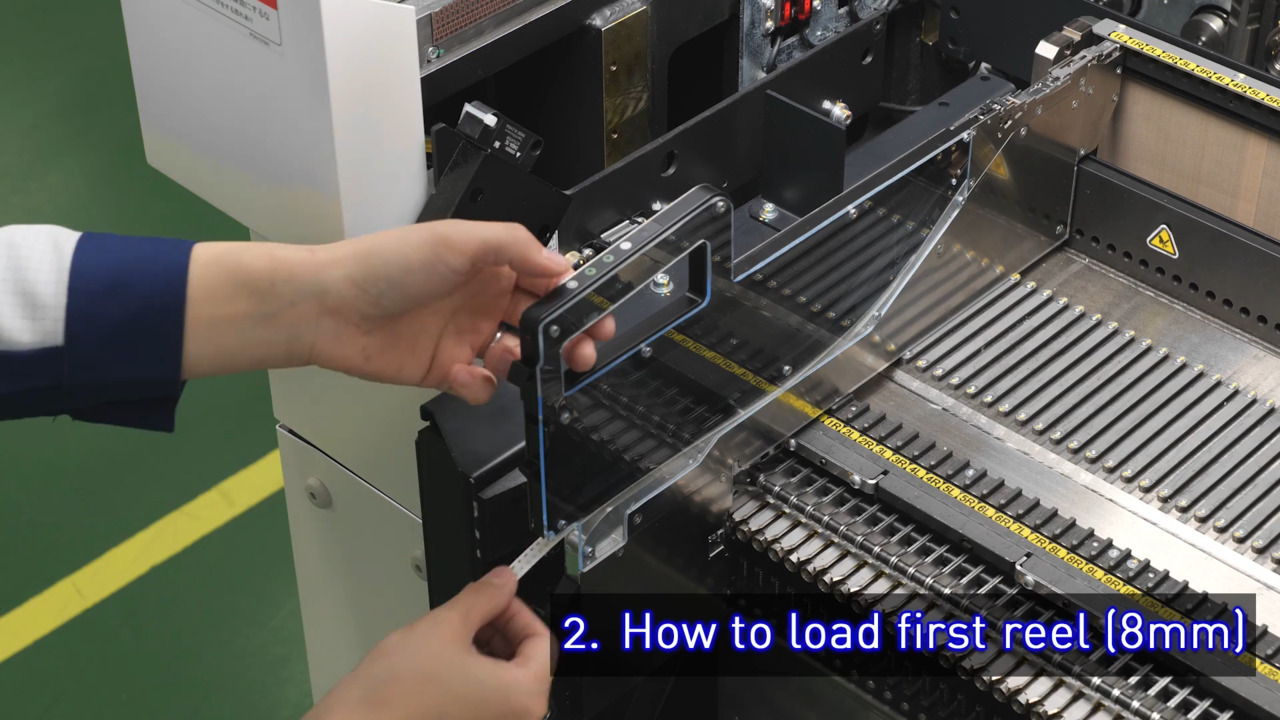

Auto setting

Automatic tape peeling and loading is completed by simply inserting the pre-processed tape to the depth and pressing a button.

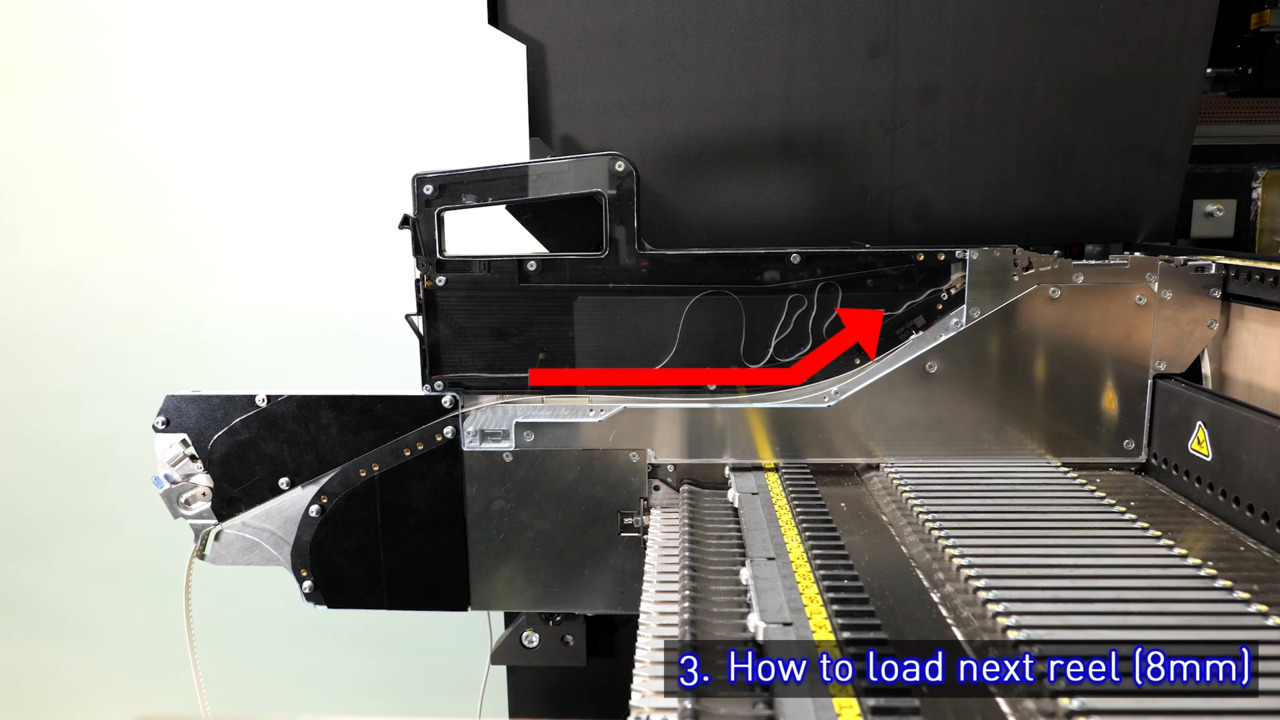

Auto loading

Optional loading unit (LU) automatically fills the next parts without splicing work

Pre-processing work is necessary to use the Auto Setting Feeder. To simplify the pre-processing work, we prepare specialized Jig.

Pre-processing (8mm protrusion)

Cover tape must protrude 8mm beyond the carrier tape tip.

Automatic Half-Cut Jig

Just set the tape tip and twist the switch to complete the pre-processing.

Manual Half-Cut Jig

Just set the tape tip in Jig and push it to remove the carrier tape.

Retrofit concept that realize "Automation" of existing Panasonic facilities without mechanical modifications

Related products

Modular Placement Machine

NPM-GH

This edge device achieves industry-leading productivity and mounting quality for Autonomous Factory. Proposes control of irregularities in the 5Ms and elimination of skill-dependent work.

Modular Placement Machine

NPM-DX

Increases throughput by manpower saving on the mounting floor. Extended functionality for the device industry.

Modular Placement Machine

NPM-WX, WXS

Covers a wider range of production types by supporting a variety of supply units and increases throughput by manpower saving on the mounting floor.

Production Modular

NPM-D3A

Adoption of the latest 16-nozzle head V3. Advancement of head drive unit motion control.

Production Modular

NPM-TT2

Direct connectivity with NPM-D3A/W2. Selectable and configurable supply unit specifications.

Production Modular

NPM-W2, W2S

Implements high-productivity and high-quality with variable-mix and variable-volume production. Supports large components and PCBs.

Custom Service

Line simulation

Tact simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components

Maintenance solution

To ensure that our mounting machines can be reliably used by our customers for many years after delivery, we not only maintain the machines, but also continue to support our customers throughout the life span of the machines, reducing production loss, stabilizing operation and improving work efficiency.

Related links

Contact

We are here to help! Contact us if you have an inquiry or question.