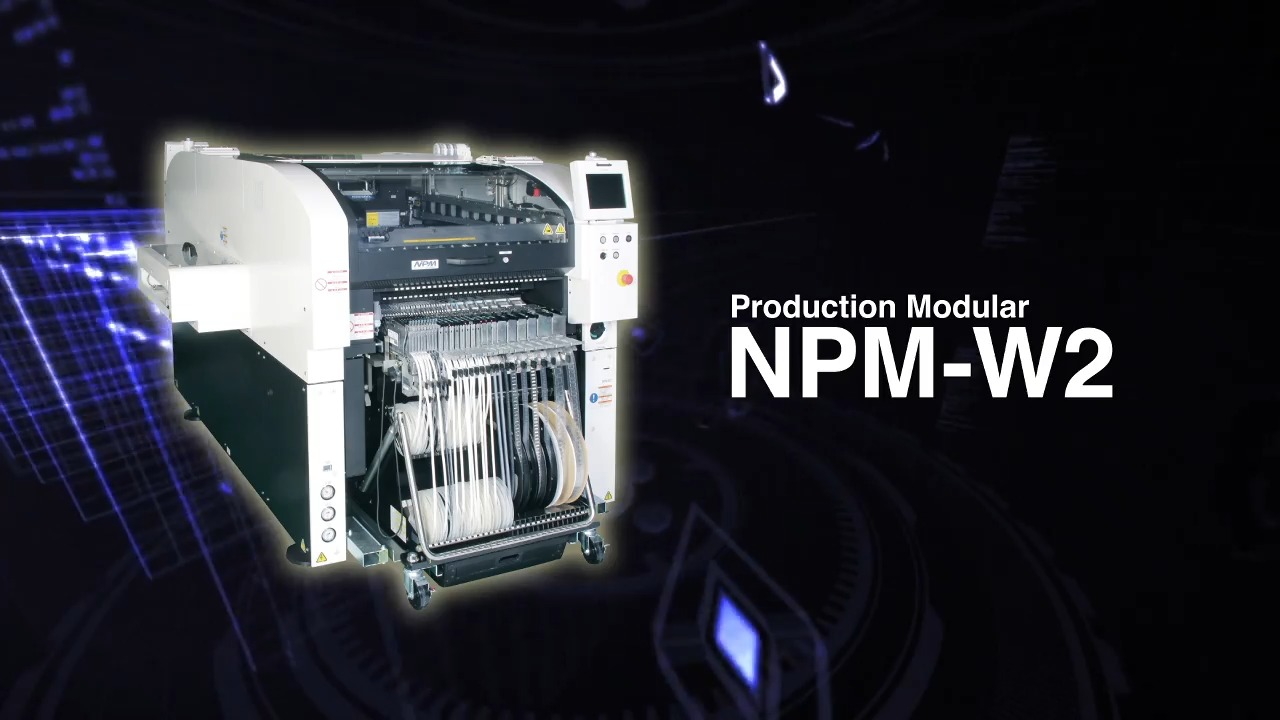

Production Modular NPM-W2

Production Modular NPM-W2

W2 is a high-productivity and high-quality mounting model with advanced productivity, model changeover ability, and component adaptability in variable-mix variable-volume production.

- High productivity and high-quality mounting achieved at the same time

- High model changeover ability

- Advancement in component adaptability and support to PCB length

※ Modular Placement Machine NPM-W2S has been discontinued.

Features and Benefits of “Production Modular NPM-W2”

High-productivity and high-quality mounting, model changeover ability, and component adaptability in variable-mix, variable-volume production

Introduction Video of “Production Modular NPM-W2”

Related products

Installed MES software

PanaCIM-EE Gen2

Support is provided for improvement in QCD in each task related to mounting, through centralized management of the entire mounting floor

Installed MES software

PanaCIM-EE Gen2

Support is provided for improvement in QCD in each task related to mounting, through centralized management of the entire mounting floor

Automation for mounting processes

We propose factory automation that replaces manual work with automated equipment for mounting-related processes.

Exhibition and Seminar Information

Information on current seminars and exhibitions is compiled and posted here. Information on past seminars and exhibitions is also available.

Custom Service

Line simulation

Tact simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components

Maintenance solution

To ensure that our mounting machines can be reliably used by our customers for many years after delivery, we not only maintain the machines, but also continue to support our customers throughout the life span of the machines, reducing production loss, stabilizing operation and improving work efficiency.