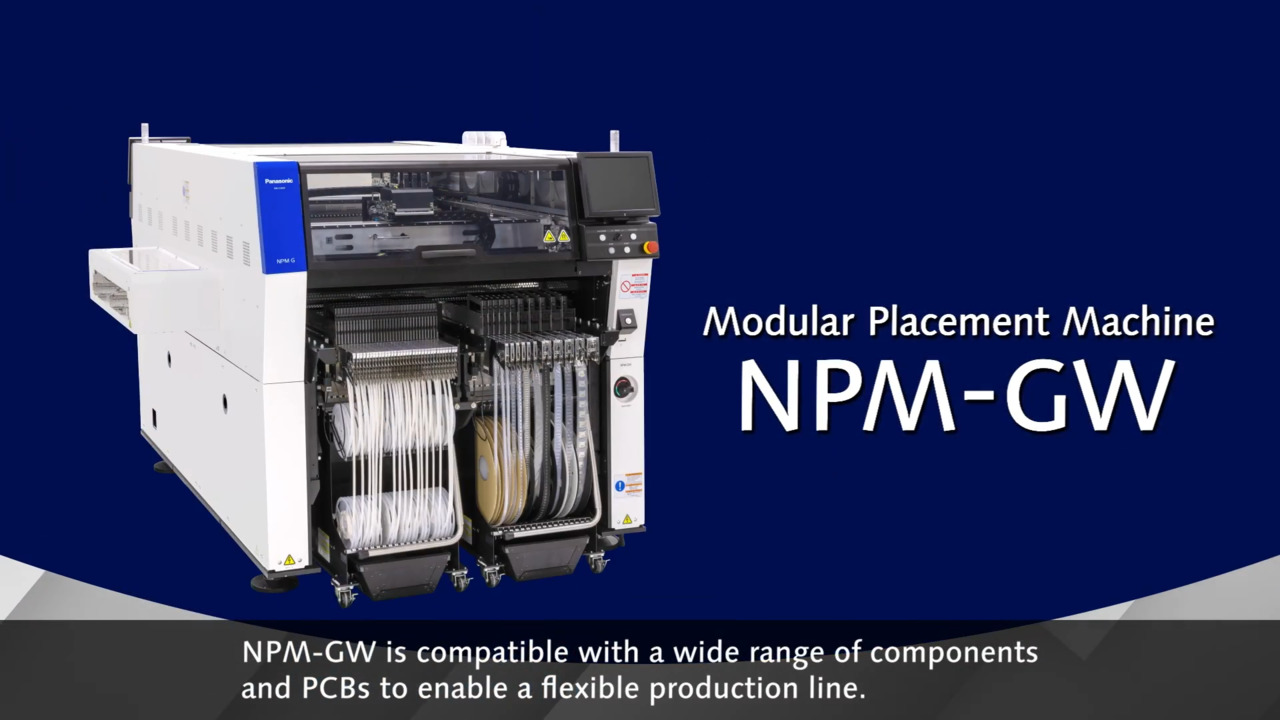

Modular Placement Machine

NPM-GW

Compatible with a wide range of components and PCBs to enable a flexible production line

Modular Placement Machine NPM-GW

Key features and functions

- Support large components and large PCBs to meet the increasing demand for Electric Vehicles (EV) and DX

- 5M process control “APC-5M” for good production and stable operation

- Various skill-less and manpower-saving features including Auto Setting Feeder

* 5M: The variable elements of a production site: huMan, Machine, Material, Method, and Measurement

Features

Modular mounter with wide range of components/PCBs compatibility

The basic performance of this modular mounter has been improved by renewing the core units, such as the placement head and recognition camera. It now supports a wide range of components and various components supply configurations, and can also handle larger PCBs. It also supports various automation and manpower-saving functions, including the Auto Setting Feeder (ASF), which automates the components supply operation, to flexibly meet the requirements of each mounting site.

Supported components range

Maximum speed and placement accuracy

Supported PCB size

Configuration example

Example configuration

Component supply units

Problems this product contributes to

Support for a wide variety of components

It can support wide variety of components, from micro to large.

Support for a wide variety of PCBs

Wide range of PCB sizes allows flexible production for various industries.

High quality placement

Minimizing the effects of variation allows for high quality placement.

Enhance skill-less and labor-saving

Reduce human-dependent work, which is one of the causes of loss and quality degradation, and reduce dependence on specific workers by making them skill-less.

Wide variety of components

High productivity mounting of a wide range of components

Placement head (new design)

Flexible head configuration for 0201 to large and tall components. Production can be performed with high productivity. When compared with the catalog speed (CPH), the NPM-GW is approximately 10% better than our conventional model NPM-WX at ±25μm condition.

Large heavy BGA components

Large, heavy components placement

The nozzle is designed for large, heavy components, and scanning operations are tailored to the component size. And 15,000 BGA balls are detected, a trend in the server industry.

Automated DIMM connector placement

High load placement / Tall component mounting

High load placement of 100N is able to eliminate pin floating, and tall component mounting up to 53mm (including PCB thickness) allows automated DIMM connector placement. (*Please consult us for applicable components.)

Adaptable to various supply section layouts

Three types of supply section units

By combining three types of supply section units, you can select a variety of supply section layouts.

Wide PCB range

Wide range of PCB types and industries

Supported PCB sizes

The number of PCB sizes supported has been expanded from previous models to accommodate a wider range of PCB types, satisfying the needs of customers in a number of industries.

Support for large PCBs

When the transfer direction dimension (L) exceeds 760 mm, the supported PCB size can be expanded up to 1,050 mm. When equipped with a front/rear extension conveyor, it can be expanded up to 1,260 mm.

High quality placement

Unit condition monitoring~analysis to optimize maintenance

APC-5M (option)

To ontrol 5M variation autonomously, unit condition can be monitored, analyzed easily to ensure proper maintenance.

5M Unit conditions are monitored in real time to control variations autonomously, enabling predictive maintenance before conditions deteriorate and preventing errors due to lack of maintenance.

Not only showing the status of each equipment, but also the entire line can be displayed on the LPC (Line Process Controller) screen for line status monitoring, and the status of target units in the line can be broken down for time-series analysis. The status after maintenance can also be checked to determine if maintenance is appropriate.

※5M : huMan, Machine, Material, Method, Measurement

Variation control with inspection machine (AOI/SPI)

APC System (APC-FF/APC-MFB2)

Maintains mounting quality by controlling variation in solder printing and component placement in conjunction with the inspection machine.

APC-FF is our unique in-line process control system that feeds forward the mounting position correction amount to the mounting machine based on the solder position data measured by solder inspection to maintain mounting quality.

The APC-MFB2 maintains mounting quality by feeding back component position data measured by the inspection machine (AOI) to the mounting machine after component placement.

Prevents mounting defects due to component setting errors

LCR checker (built-in type)

Measuring electrical characteristics of components prevents mounting defects due to component mis-setting. Stable measurement is possible by holding the posture and position of the component with an adhesive material, and by pressing down on the component with a metal lever, highly accurate measurement is possible regardless of the nozzle used.

Skill-less and labor-saving

Automation of components supply operations

Auto Setting Feeder

Automated supply of 8 to 104 mm wide reels of paper and embossed tape. The loading unit can be used to automate not only new tape supply, but also the next tape supply.

Automatic setting reduces set-up time and skill, while automatic loading eliminates the work for splicing, realize skill-less work.

Error recovery work performed offsite location

Remote Operation

Error recovery operations can be done remotely and efficiently, preventing on-site operators from being late in noticing error signals and allowing on-site operators to concentrate on supplying components, thereby improving productivity and reducing manpower.

Specifications

*The above information includes options. Also, please contact us for details, as it may differ depending on usage conditions.

Related products

New Parts Feeder

Auto Setting Feeder

Greatly reduces working time by automating parts supply work in the SMT process. ASF supports 8~104 mm width tape parts (Paper, Emboss).

Modular Placement Machine

NPM-GH

This edge device achieves industry-leading productivity and mounting quality for Autonomous Factory. Proposes control of irregularities in the 5Ms and elimination of skill-dependent work.

Screen Printer

NPM-GP/L

Optimizes the screen printing process. Equipped with automation functions, also capable of high-accuracy screen printing.

Custom Service

Line simulation

Tact simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components

Maintenance solution

To ensure that our mounting machines can be reliably used by our customers for many years after delivery, we not only maintain the machines, but also continue to support our customers throughout the life span of the machines, reducing production loss, stabilizing operation and improving work efficiency.