APC (Advanced Process Control) System

Do you face any of these problems?

- Variation in mounting of the components even after ensuring adequate maintenance and accuracy of printers and mounting machines

- Accurate mounting of the components at the correct position is not possible

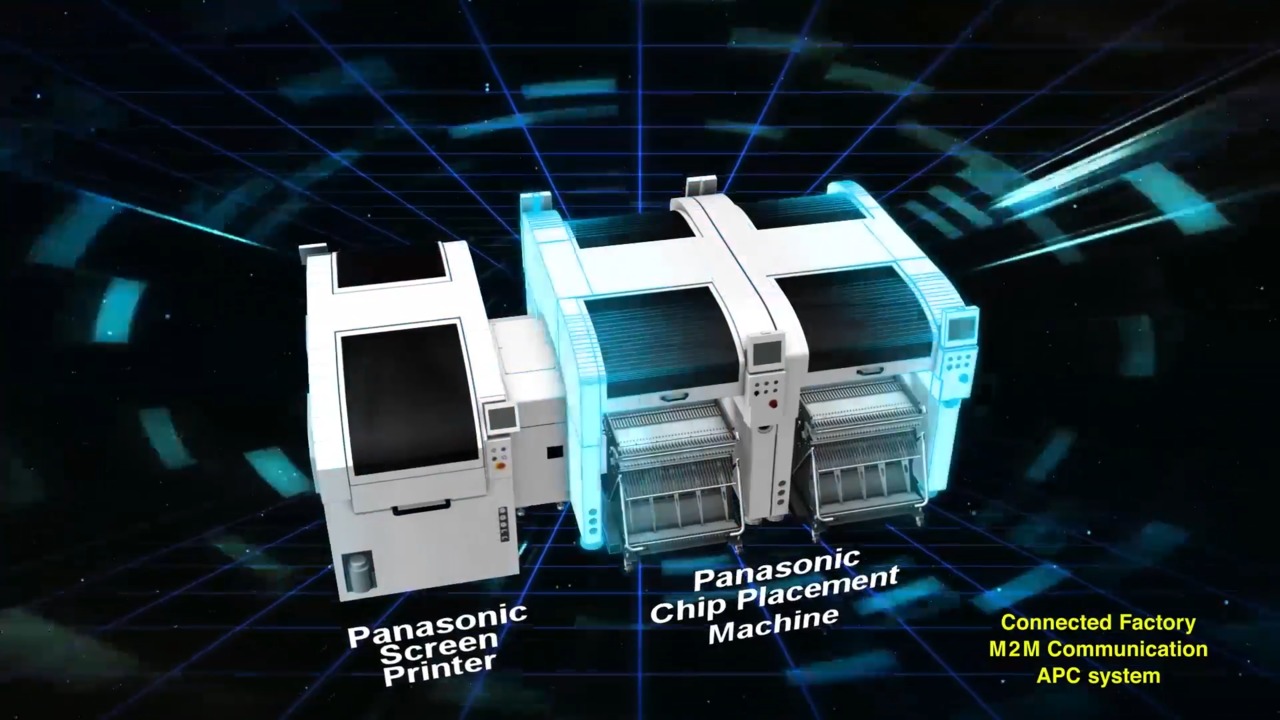

Panasonic’s APC (Advanced Process Control) System sends equipment variations from the inspection equipment to the printer and mounting machine, performs corrections automatically for placement of components at the correct position.

Feedback control (APC-FB)

This function statistically processes the solder measurement results from the 3D solder inspection device and sends feedback to the printer to correct the positional displacement of land and solder to the correct position. This stabilizes the printing quality automatically since the feedback value can be set arbitrarily utilizing Panasonic’s know-how accumulated over many years.

Feedforward control (APC-FF)

This function sends feedback of the center of gravity position of the solder for each mounting circuit from the 3D solder inspection device to the mounting machine, maximizing the self-alignment effect during reflow by aligning the mounting position with the solder center of gravity. Panasonic’s many years of know-how enables stable production of good products.

Feedback control (APC-MFB2)

This measures the post-mounting displacement of the mounted components with the visual inspection equipment (AOI) and sends the feedback of the correction amount to each nozzle of the mounting machine. This function automatically corrects equipment variations and maintains accurate mounting at the correct position. The target components have expanded to include chip components and components with leads, bottom termination components and connectors, etc., making this useful for a wide range of products.

Introduction Video of “APC-System”