Welding Machines /

Robots / Lasers

Featured Products and Solutions

Introduction to featured products and solutions.

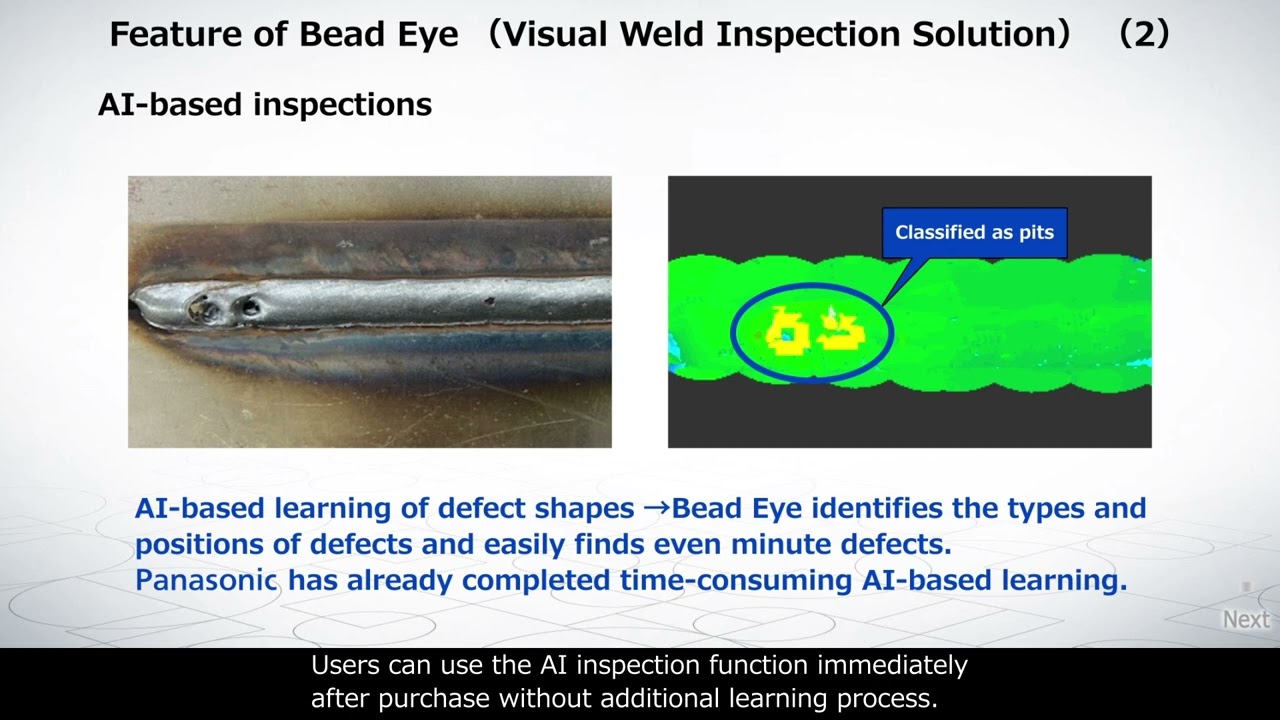

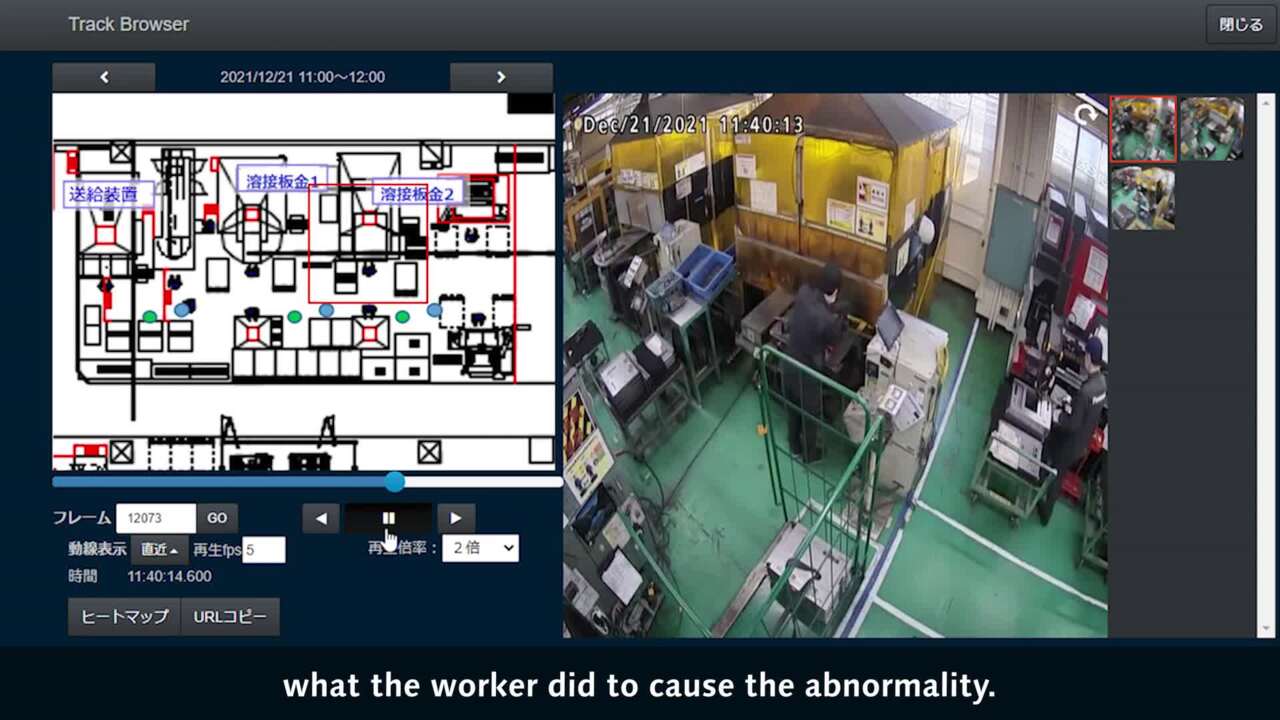

Significant improvement with visualization of the welding process

Panasonic Kaga Factory could realize the visualization of the welding robot process by introducing Integrated Welding Management System iWNB. They could visualize the worksite using cameras and eliminate wasteful and uneven human movements to achieve a 15% reduction in cycle time.

Improvement of welding quality with robots

ITECH introduced the arc welding robot TAWERS to establish a work environment that is not dependent on the welding skills of individuals and created a better workplace where women can also play an active role.

WG4 / G4 Arc Welding Robot

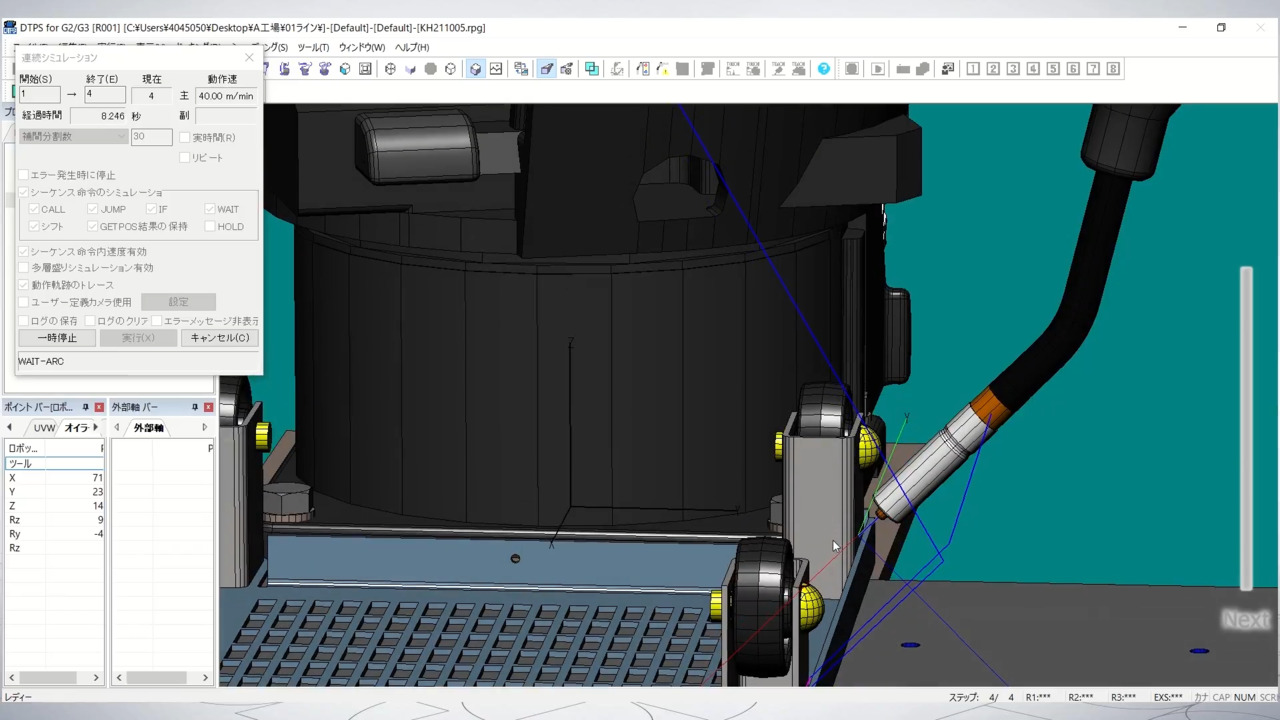

The WG4 / G4 is the flagship model of our welding robots.It solves customers' problems through various approaches such as further evolved weldability, ease of use, and safety.

See detailsCategory List

Welding and Cutting Machines

Panasonic offers a wide variety of models to meet your needs including high-performance full digital devices.

Arc Welding Robots

High-performance robots, including the welding power source integrated robot “TAWERS”, are introduced here by model.

We support for total solution of robot + system for manpower saving

We propose not only the welding technology but also the digitization and automation of the work that workers usually carry out during the pre- and post-welding processes. We will enhance our usefulness, which can only be realized through the continuous development of welding products for more than 60 years.

■Solutions by Process

Offering extensive support from welding consulting to demonstration testing

We offer welding consulting and demonstration testing before introduction. We solve the problems of our customers by combining the latest technologies and manufacturing methods with the know-how we have accumulated.

Case Studies and Solutions

■Search by Case Studies

Videos of case studies and customer testimonials.

Reliable service provision was also a decisive factor

Maruo Kousakusho could realize “ultra” low spatter by installing the arc welding robot TAWERS having the option of the latest Super Active manufacturing method. They could reduce the time spent on spatter removal by more than 90%.

Low spatter even when welding thick plates

Yahata Seiko could achieve deep penetration and neat bead appearance with high power TAWERS HD pulse welding. They could achieve full robot production with the high-power specification and 100% duty cycle.

■Search by Industry

Automation

Collection of case studies of systems for various industries. Use this information when you are considering the equipment.

General-Purpose System Field

Collection of case studies of simple systems. Case studies of general-purpose systems available to customers in a wide range of industries are listed.

Automotive Field

Collection of case studies for automobiles. Case studies of systems for different components are listed.

Construction Equipment Field

Collection of case studies for construction equipment. Many case studies of systems for large components are listed.

Infrastructure Field

Collection of case studies for infrastructure. Case studies of systems for different components are listed.

Processing

Collection of processing examples by industry. Here are processing examples including automobile and construction equipment components.

■Search by Material

Videos of case studies of actual problems that have been solved.

Automation of TIG welding

Thin plate TIG welding requiring proficient techniques. Once taught, TAWERS can reproduce the skills of an experienced TIG welder repeatedly.

Reduction of spatter removal man-hours

Super Active TAWERS solves the problems of spatter removal. Welding with almost no generation of spatter can be realized.

Reduction of tact time

High-speed welding with TAWERS. With the S-AWP manufacturing method, welding can be performed at more than twice the speed of conventional welding methods. (Compared with conventional)

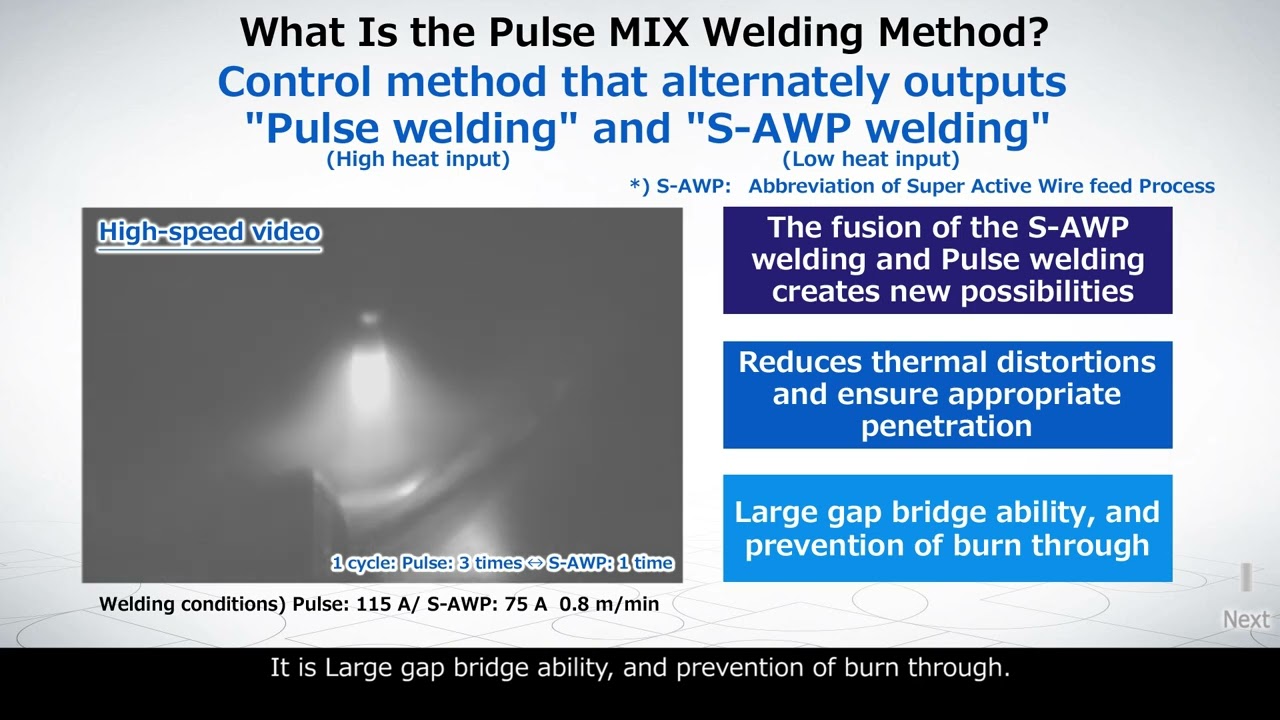

Burn through in thin plate welding

Control of weld heat input when welding thin plates is difficult and burn through is the biggest challenge. Heat input control software solves this problem.

■Solutions by Process

Processing (Welding)

Super Active TAWERS (Thin Plates with Gaps)

Support

Global Network

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website for Panasonic Shoyokai

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.

News

-

July 22, 2024

Information

-

May 31, 2024

Information

-

August 03, 2023

Information

-

July 03, 2023

Information

-

May 31, 2023

Press Release

-

May 18, 2023

Information

Welding Machines / Robots / Lasers renewed.

Contact

We are here to help! Contact us if you have an inquiry or question.