Welding Robot Systems

G4 series (WG4 / WGH4 / G4)

Overview

The G4 series is flagship models of welding robots.

These robots solve customer challenges through a variety of approaches, such as by providing further evolved weldability, ease of use, and safety.

WG4: Welding power source integrated type (TAWERS)

WGH4: High current welding power source integrated type (TAWERS)

G4: Welding power source separated type

Features

-

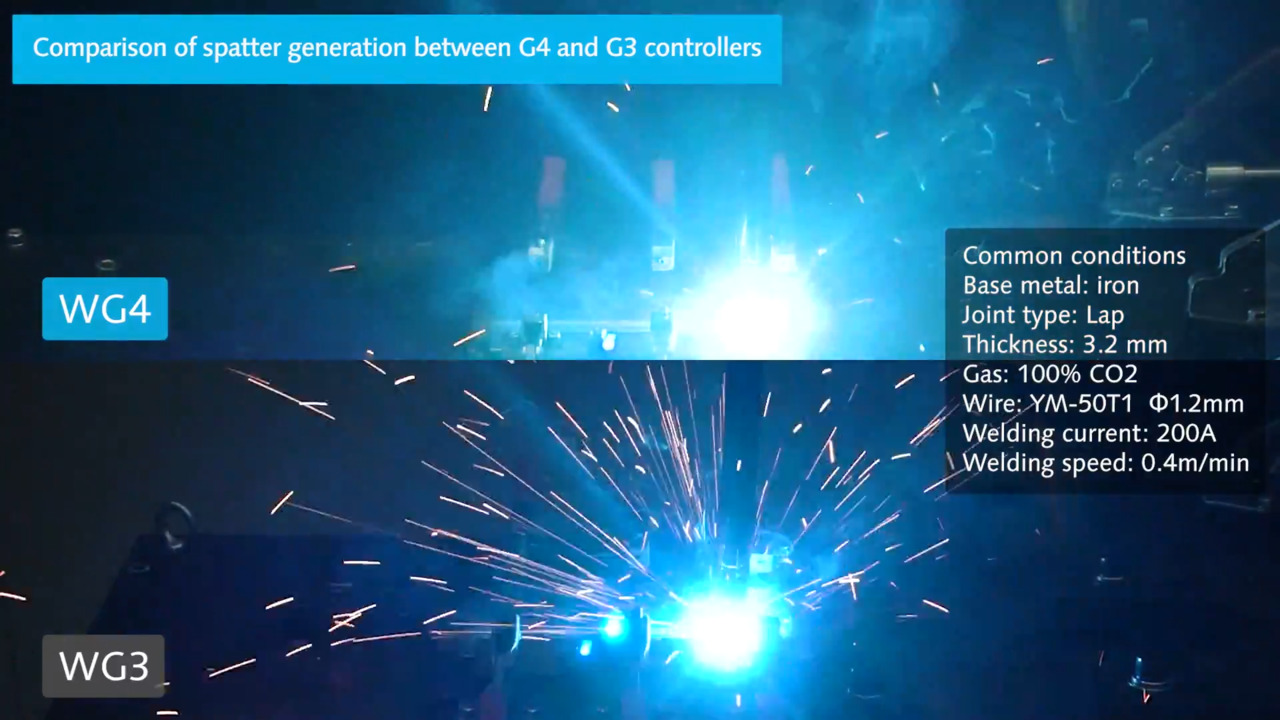

Reduces spatter by approximately 60% with the MTS-CO2 welding method (WG4)

-

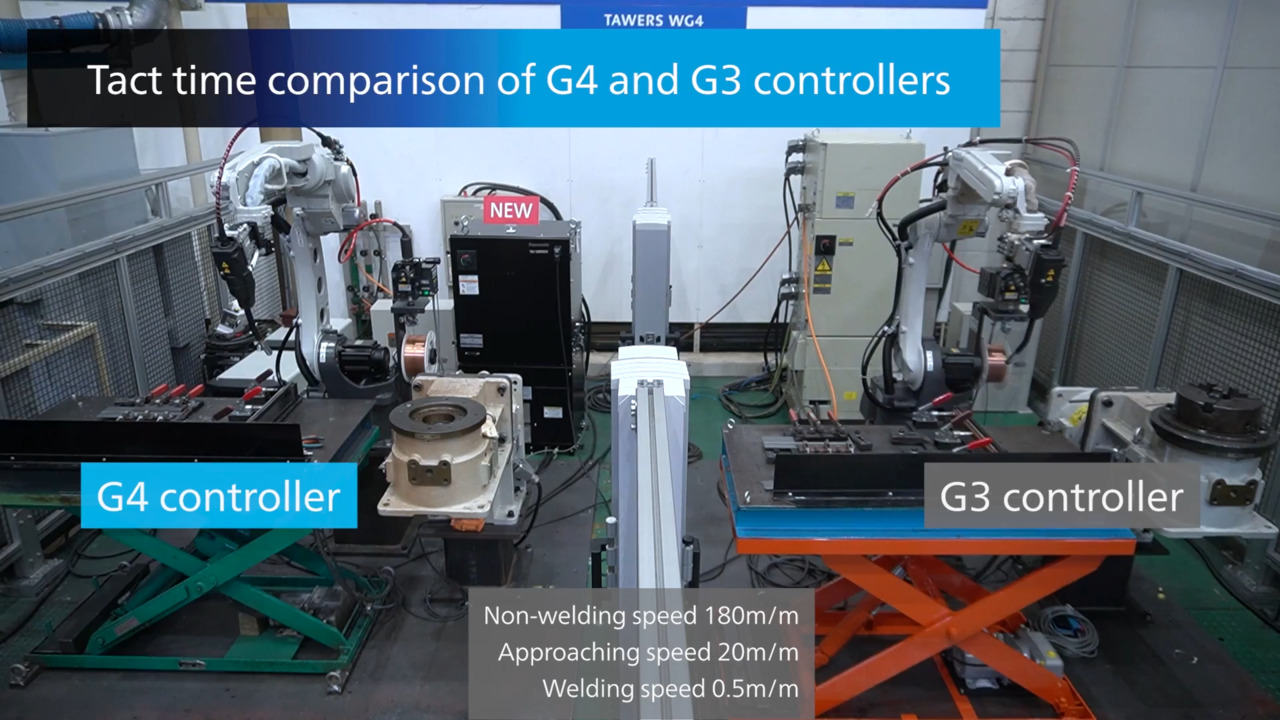

Welding control optimization according to robot posture reduces cycle time (WG4 / WGH4 / G4)

-

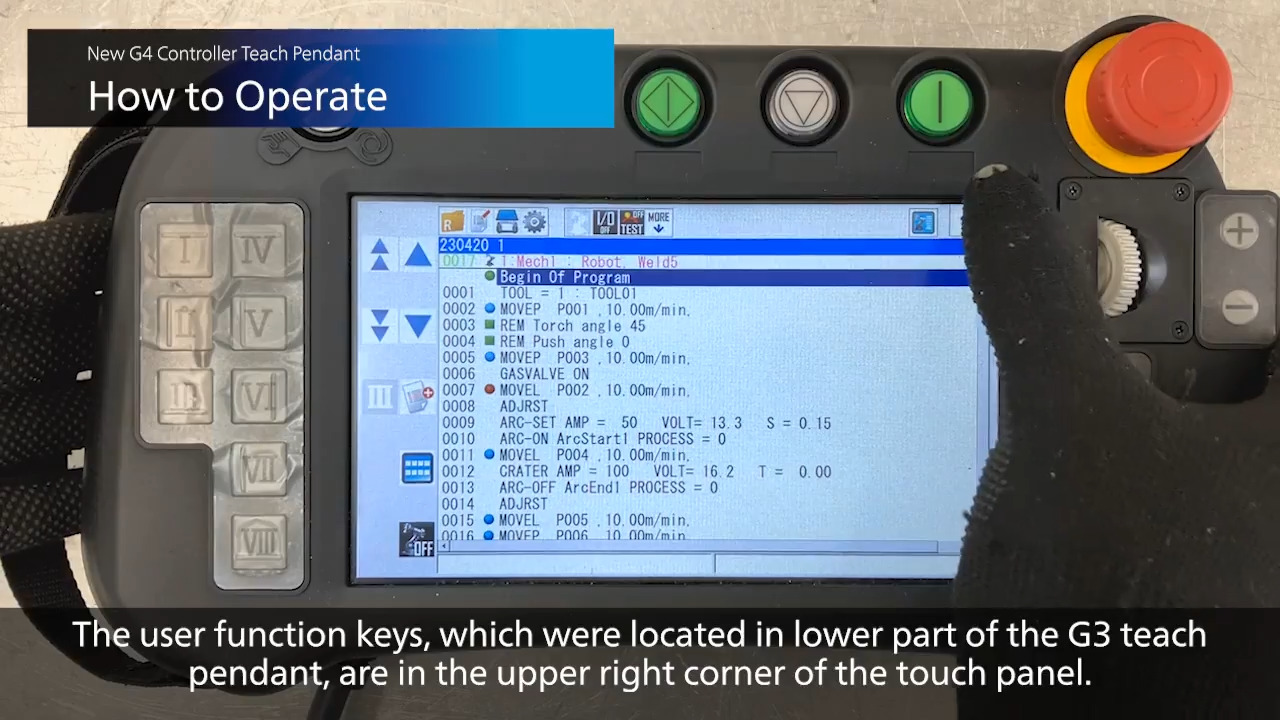

The teach pendant equipped with a touch panel further improves ease of use (WG4 / WGH4 / G4)

-

Eliminating the need for an external step-down transformer reduces the man-hours required for setting up at sites outside Japan (WG4 / WGH4 / G4)

-

The conformance to the OPC UA standard facilitates integration with peripheral devices (WG4 / WGH4 / G4)

-

High current up to 500A, suitable for thick plates (WGH4)

Advanced welding method "AWP4"

AWP4(Active Wire Process 4) can be used with TAWERS (WG4) to improve productivity through low spatter and high-speed welding.

Assumed Customer Challenges

Spatter reduction

The MTS-CO2 welding method, which is the basic function of TAWERS, has significantly evolved, demonstrating its spatter reduction effects in the high-current range.

Ease of use

The teach pendant equipped with a touch panel has enabled more intuitive and easier operation. Welding Navigation also allows easy condition setting.

Welding defects

These models enable the analysis of welding results in a more detailed manner than conventional models. Users can expect enhanced welding quality through the in-depth analysis of welding results.

Features and Effects of WG4 / WGH4 / G4

The further evolution of the performance of the MTS-CO2 welding method contributes to reduced spatter (WG4)

- Significantly improved weldability in the high current range of 200 A or higher

- Reduces spatter by approximately 30% and 60% in the 200 A range and 260 A range, respectively, compared to WG3

- No need to purchase optional products since these improvements can be achieved through the basic function of TAWERS

- Improved weldability is highly effective for the visualization and reduction of welding defects

Welding control optimization according to robot posture reduces cycle time (WG4 / WGH4 / G4)

- The basic performance has been enhanced through improved CPU performance and memory capacity

- The maximum speed of each axis has been improved by up to 27% (compared to the G3 controller)

The new teach pendant equipped with a touch panel has further improved ease of use (WG4 / WGH4 / G4)

- A touch panel has been installed for the operation display without changing the basic operation

- The panel can be operated by users wearing gloves

- The display features a tidy design with integrated functional buttons

- The characters on the display can be enlarged, reducing the risk of pressing the wrong keys and significantly improving visibility

Easy to set up at factories outside Japan without the need for a step-down transformer (WG4 / WGH4 / G4)

- There is no need for an external step-down transformer, which can achieve reduced costs and a more compact footprint

- Failure risks can be reduced with fewer connected devices and cables

* When setting up these robot systems in Japan, an input power supply is required according to the specifications of each model.

Please note that if you cannot prepare the required power supply, then a separate transformer is required to convert the input voltage to 200 V.

Enhanced compatibility with peripheral devices by conforming to the OPC UA global standard for industrial interoperability (WG4 / WGH4 / G4)

- OPC UA-compliant devices possess connection compatibility, thereby enabling secure and seamless data exchange between them

* OPC UA-compliance is an optional function. In order to ensure data exchange between devices, all of them must be OPC UA-compliant.

The software-based safety mechanism enables more flexible and safer work environments (WG4 / WGH4 / G4)

- Conventional hardware limit switches for manipulators have been replaced with software-based monitoring

- Safety signals such as for emergency stop can be exchanged by using communication signals

- Complex safety circuits, which were conventionally designed by combining PLCs, switches, and relays, can now be configured with software, thereby facilitating specification changes

External dimensions

■Controller external dimensions (WG4)

■Controller external dimensions (WGH4)

■Controller external dimensions (G4)

■Teach pendant external dimensions

Support

Global network

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website for Panasonic Shoyokai

Website dedicated page for members of Panasonic Shoyokai.

You can download the application form to join the membership website P-Web.

Contact

We are here to help! Contact us if you have an inquiry or question.