Overview

AWP4 is optional software dedicated to the TAWERS robot, which contributes to solving problems such as spatter reduction, welding speed improvements and securing weld penetration.

This is exclusive software for TAWERS (WG4). Separate peripheral equipment is required for use in addition to the software.

Features and effects

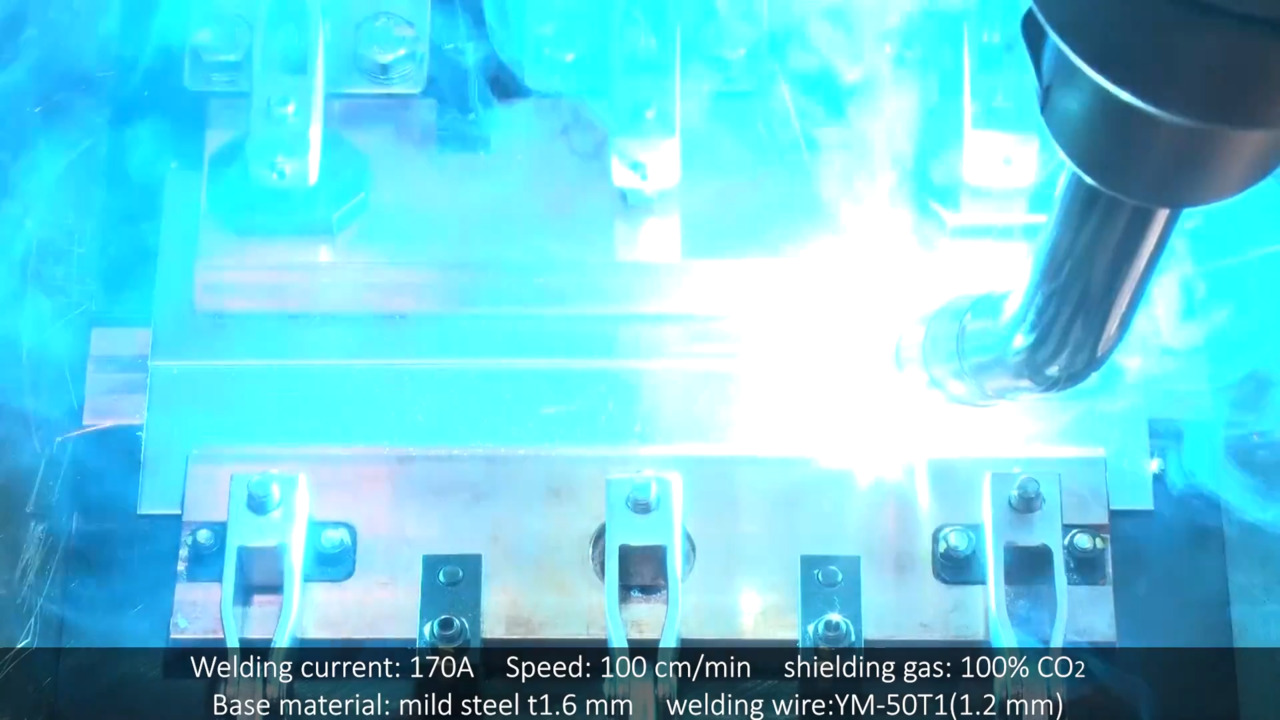

Significant reduction of spatter and higher quality bead appearance.

High-precision wire feeding and welding waveform control can significantly reduce the amount of spatter.

When welding with CO2 gas, spatter is reduced by 98% compared to conventional welding method*.

MAG and MIG gases can also be used as shielding gas, making the system suitable for welding a wide range of materials.

In addition, the evolution of the robot controller and welding torch and the accompanying improvements in wire feed control have stabilised the molten puddle compared to conventional welding methods, enabling a flatter bead appearance.

※ Welding current: 300 A Speed: 100 cm/min Shielding gas: 100% CO2

Base material: mild steel t3.2 mm Welding wire: YM-50T1 (1.2 mm)

※ The welding power source being compared is the YD-350GR3.

Air-cooling torch mechanism ensures high duty cycle

The AWP4 continues to be equipped with the conventional air-cooling torch mechanism for active wire welding as standard.

This enables the AWP4 to achieve duty cycle of 80 % at 310 A output for CO2 gas welding, making it suitable for heavy duty production.

Contact

We are here to help! Contact us if you have an inquiry or question.