Bead Eye (Visual Weld Inspection Solution)

Overview of Bead Eye (visual weld inspection solution)

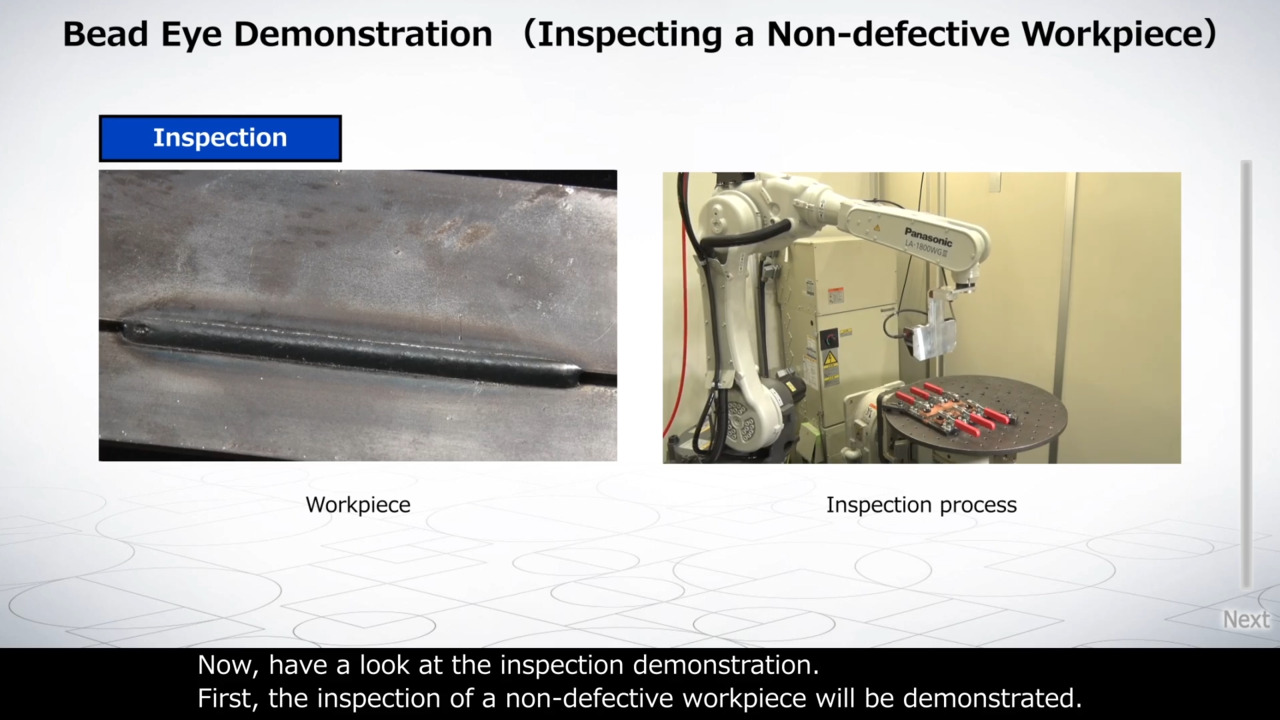

Bead Eye is a solution that provides “labor-saving” and “enhanced traceability” by automating the manual visual inspection.

Scanning weld beads

A scanner attached to the robot scans bead shapes.

Inspection judgment

Logic #1: Master comparison inspection

Logic #2: AI inspection

Traceability

Inspection result data is stored in the industrial PC

Bead Eye (Visual weld inspection solution) Features

Inspection logic #1: Master comparison inspection

Setting up is easy because it is a comparison inspection to the master data.

It compares the target products to the pre-set master data, and judges pass/fail based on the concordance rate.

Inspection logic #2: AI inspection

The AI engine that has been trained at Panasonic will not miss the welding defects difficult for automatic visual inspection before.

AI learns the shape of the defects and judges its type and position. It can inspect the smallest defects easily.

Customer benefits

A wide range of welding defects can be detected by the robot by combining AI inspection and master comparison inspection.

| Inspection logic | |||

|---|---|---|---|

| Defects | [1] Master comparison inspection |

[2] AI inspection |

Bead Eye ([1]+[2]) |

| Comparison with master |

|

|

|

| Chipping of bead |

|

|

|

| Out-of-line bead |

|

|

|

| Excess/under weld metal reinforcemen |

|

|

|

| Over/under bead width |

|

|

|

| Over/under bead length |

|

|

|

| Perforation |

|

|

|

| Pit |

|

|

|

| Undercut |

|

|

|

| Spatter |

|

|

|

Collaboration (co-creation)

We will continue to accelerate co-creation and contribute to the development of the industry by addressing pressing issues such as improving short of labor and processing quality.

System Configuration

We offer total weld bead inspection equipment other than robots.

■ System configuration example (TM-1400G3)

Precautions Upon Purchase

Please make sure to read the precautions below before purchasing Bead Eye.

- Applicable models are TM/TL/TS/ LA-series robots connected to G3 or TAWERS (WG3/WGH3) type controller.

Please contact your nearest sales office for details. - This inspection function is only to inspect welding beads of CO2/MAG welding using mild solid wire.

- This inspection function is capable of performing ideal inspection by conducting various settings and teaching suitable to the applied workpiece, processing conditions and production facilities. This product does not guarantee the quality of the inspected workpiece.

- It is not applicable to other purposes, such as inspection for MIG welding, TIG welding and laser welding.

- This inspection function is capable of performing ideal inspection by conducting various settings and teaching suitable to the applied workpiece, processing conditions and production facilities. This product does not guarantee the quality of the inspected workpiece.

- Users of this product should guarantee the final quality of the workpiece.

- It cannot be used in an environment where strong ambient light, such as CO2/MAG/MIG/TIG welding, exists in the same work area.