Case Studies

Here are some actual case studies and customer testimonials.

Global Customer’s Case Studies

Welding technology satisfied by the automotive industry

Utilizing S-AWP technology in the automotive industry, where weight reduction is required. Easy operation, high-performance robot contribute to the retention of human resources.

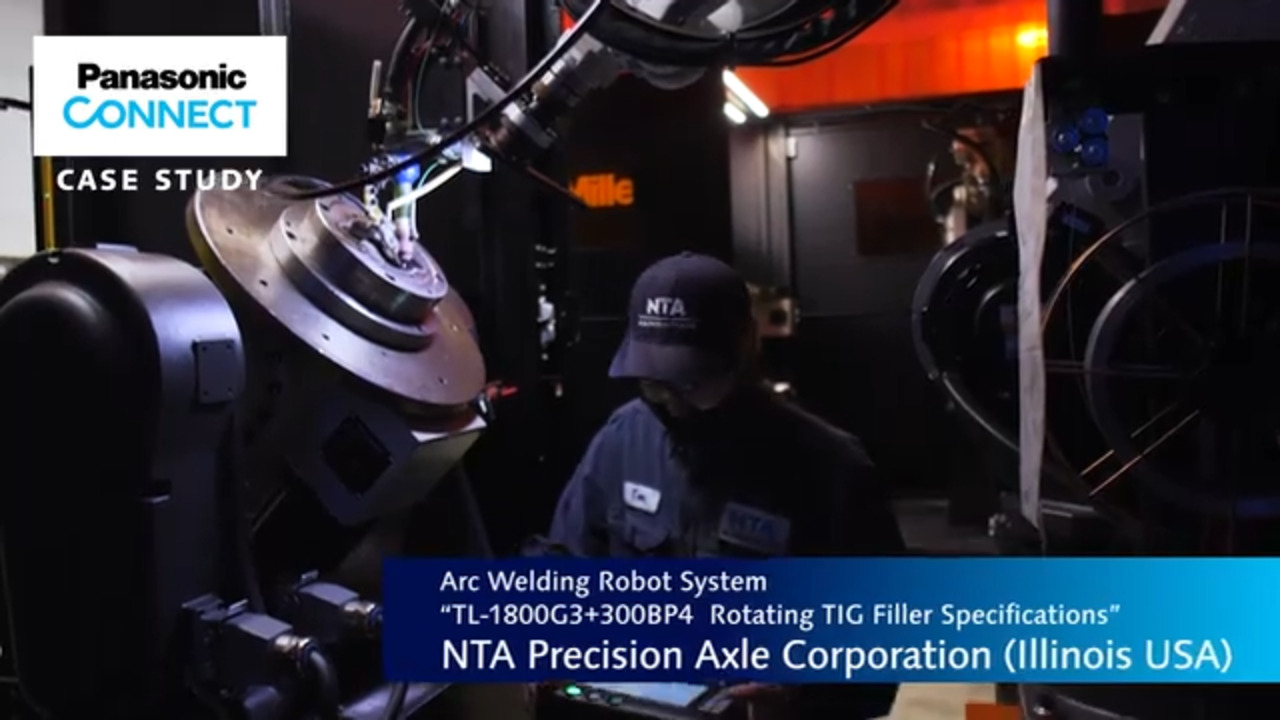

Significant cost reduction with TIG robot introduction

Regeneration of outsourced “Blade”(TIG welding) is made in-house, greatly reduced lead time and cost. In this case, NTA successfully recovered investment costs in a year and a half.

Domestic Customer’s Case Studies

Reliable service provision was also a decisive factor

Maruo Kousakusho could realize “ultra” low spatter by installing the arc welding robot TAWERS having the option of the latest S-AWP technology. They could reduce the time spent on spatter removal by more than 90%

Low spatter even when welding thick plates

Yahata Seiko could achieve deep penetration and beautiful bead appearance with high power TAWERS HD pulse welding. They could achieve full robot production with the high-power specification and 100% duty cycle.

Improvement of welding quality with robots

I TECH introduced the arc welding robot TAWERS to establish a work environment that is not dependent on the welding skills of individuals and created a better workplace where women can also play an active role.

High-quality welding without relying on individual skills

Panasonic Kaga Factory could realize high-quality welding by installing Laser Processing Robot LAPRISS without relying on special skills. They could successfully reduce costs by approximately 40% and solve the problem of labor shortage.

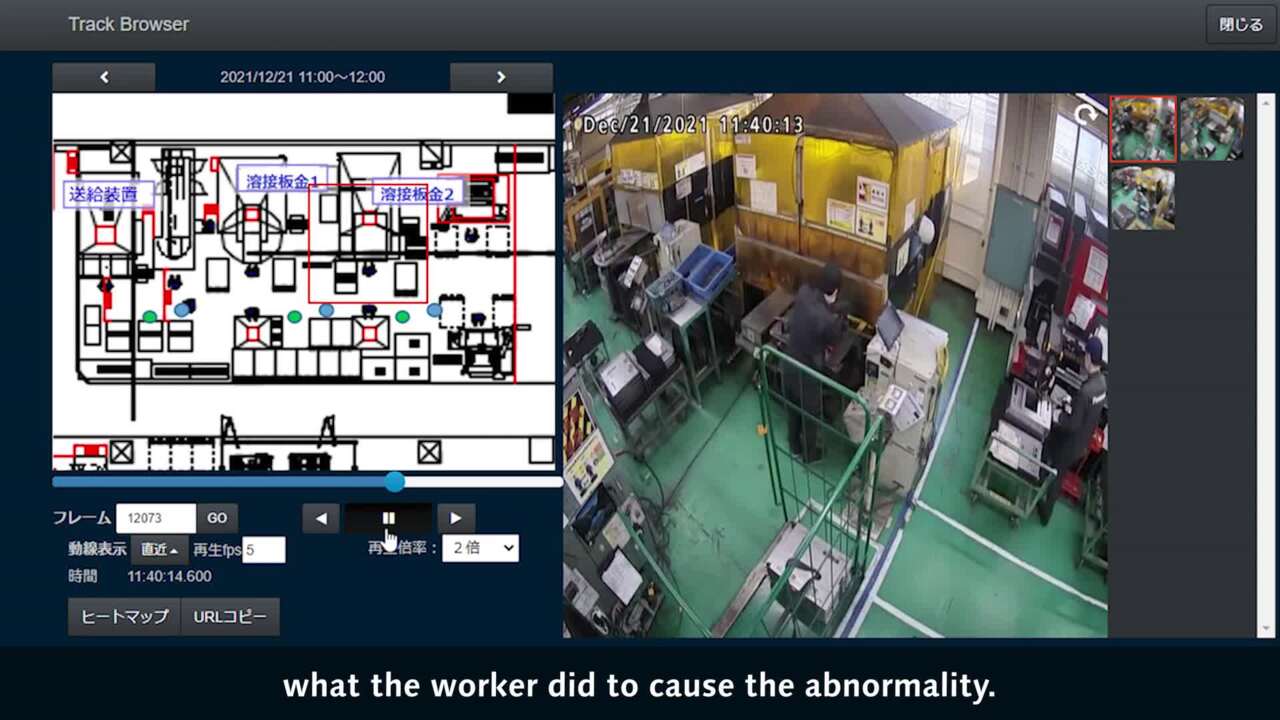

Significant improvement with visualization of the welding process

Panasonic Kaga Factory could realize the visualization of the welding robot process by introducing Integrated Welding Management System iWNB. They could visualize the worksite using cameras and eliminate wasteful and uneven human movements to achieve a 15% reduction in cycle time.

Specialized software enables difficult brazing welding

Example of brazed welding of parts used in fuel tanks.

Brazing options have been added to S-AWP to significantly reduce the time required to set welding conditions and achieve high-quality welds.

Robotization of human work

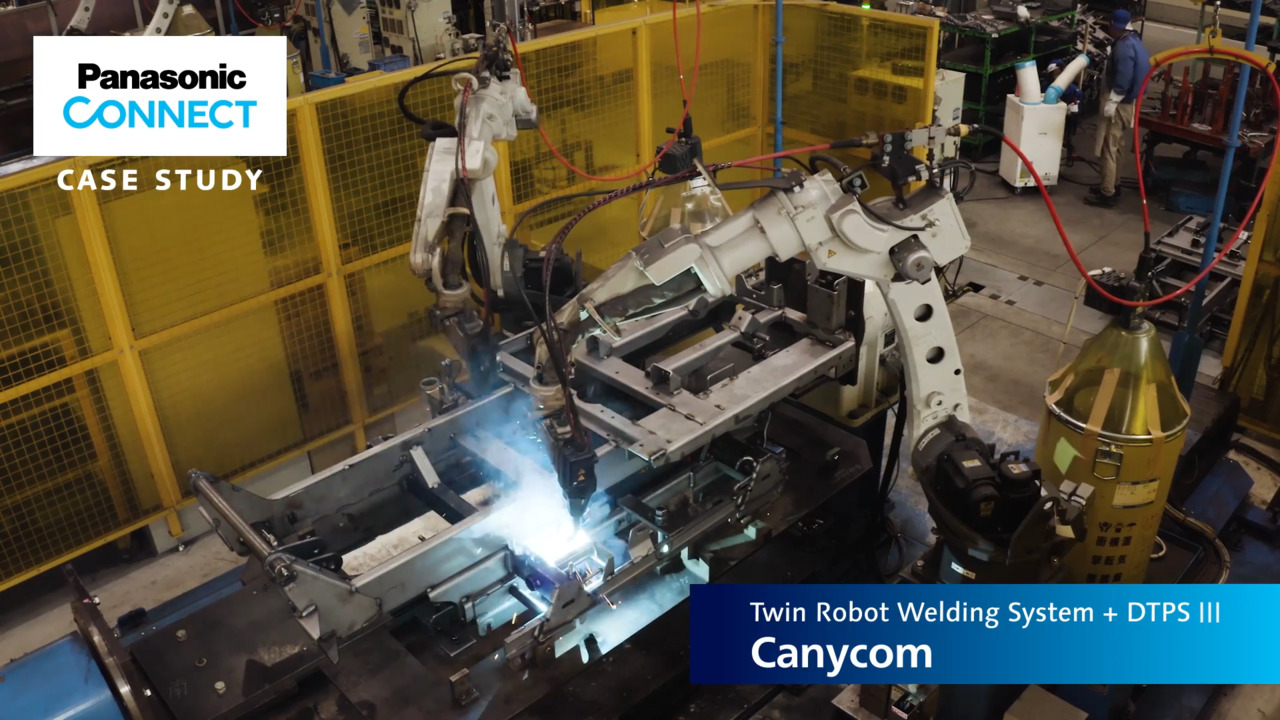

By constructing a line that combines welding robots and handling robots, the automation rate of the entire process was greatly increased.

Off-line teaching improves productivity

Off-line teaching software "DTPSⅢ" allows you to create programs on a PC without stopping robot operation.

Support

Global network

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website for Panasonic Shoyokai

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.