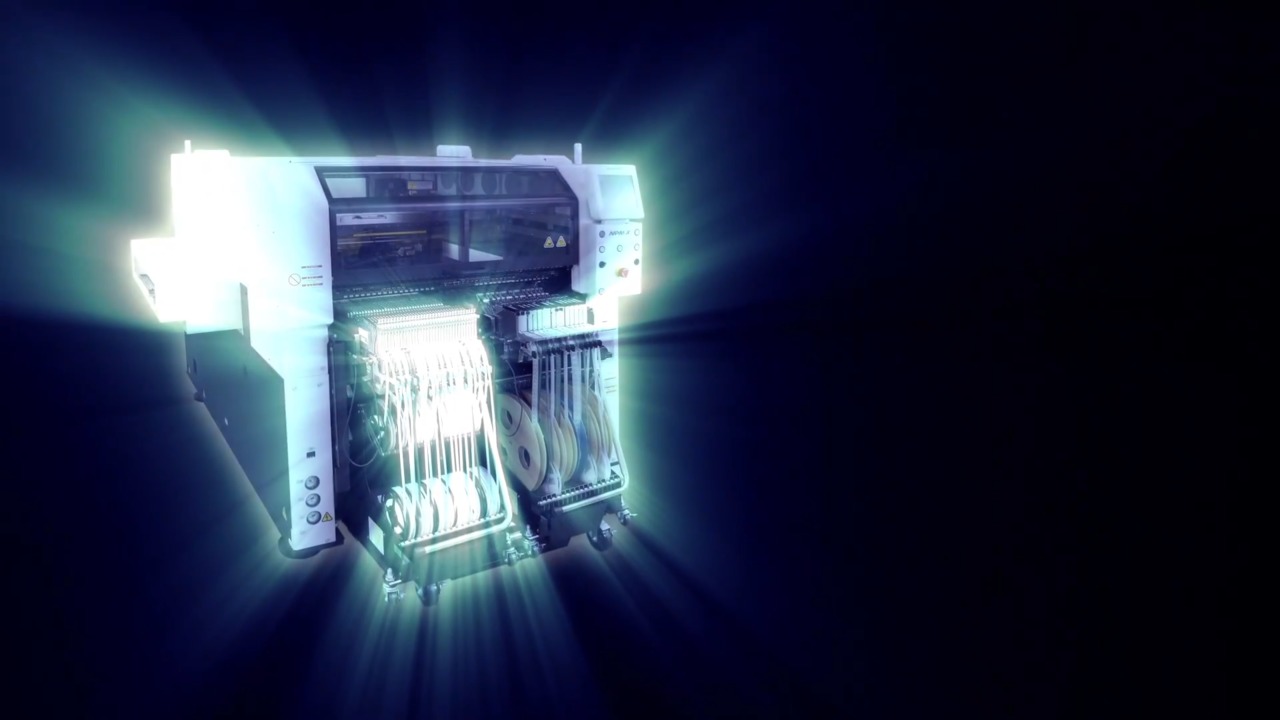

Modular Placement Machine NPM-WX

Modular Placement Machine NPM-WX

We propose a mounting line to achieve a smart factory with high productivity and high quality geared toward labor-saving.

- Evolved basic performance

- High productivity and high-quality mounting

- Comparison with W2 (productivity, accuracy)

- Expansion of production style

- Various feeder configurations

- New tray feeder (24-component type tray feeder)

- Realization of smart factories - Labor-saving functions

- Automatic recovery 1, 2 remote operation AOI display function

- Realization of smart factories - Quality improvement functions

- Recognition before pickup

※ Modular Placement Machine NPM-WXS has been discontinued.

Features and Benefits of “Modular Placement Machine NPM-WX”

Realization of flexible line configuration with expansion of compatible components for various placement heads

Four types of parts supply units allow for various parts supply layouts

30 stations

Feeder cart

17 stations

Feeder cart

24-component type

Tray feeder

Tray stocker

Mounting line APC-5M*1

*1: APC-5M is to be used with NPM-WX only. Not applicable for NPM-WXS.

By monitoring real-time “5M conditions” and “machine operations”, it detects any changes (variations) in 5M, and performs more intelligent 5M process control and predictive maintenance of the line to realize production of good products and stable operation.

*2: Under development

APC-5M: Real-time unit monitoring

The condition of the subject unit is monitored in real time, and based on the changes in the monitored values, the user is notified of maintenance timing and conditions that may interfere with production.

This function allows maintenance to be performed at optimal timing.

Introduction video of “Modular Placement Machine NPM-WX”

Related products

Related product series

Installed MES software

PanaCIM-EE Gen2

Support is provided for improvement in QCD in each task related to mounting, through centralized management of the entire mounting floor

Integrated line management system

iLNB

Optimization of the entire production line by “connecting” Panasonic machines, non-Panasonic machines, and higher-level systems

Automation for mounting processes

We propose factory automation that replaces manual work with automated equipment for mounting-related processes.

Exhibition and Seminar Information

Information on current seminars and exhibitions is compiled and posted here. Information on past seminars and exhibitions is also available.

Custom Service

Line simulation

Tact simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components

Maintenance solution

To ensure that our mounting machines can be reliably used by our customers for many years after delivery, we not only maintain the machines, but also continue to support our customers throughout the life span of the machines, reducing production loss, stabilizing operation and improving work efficiency.