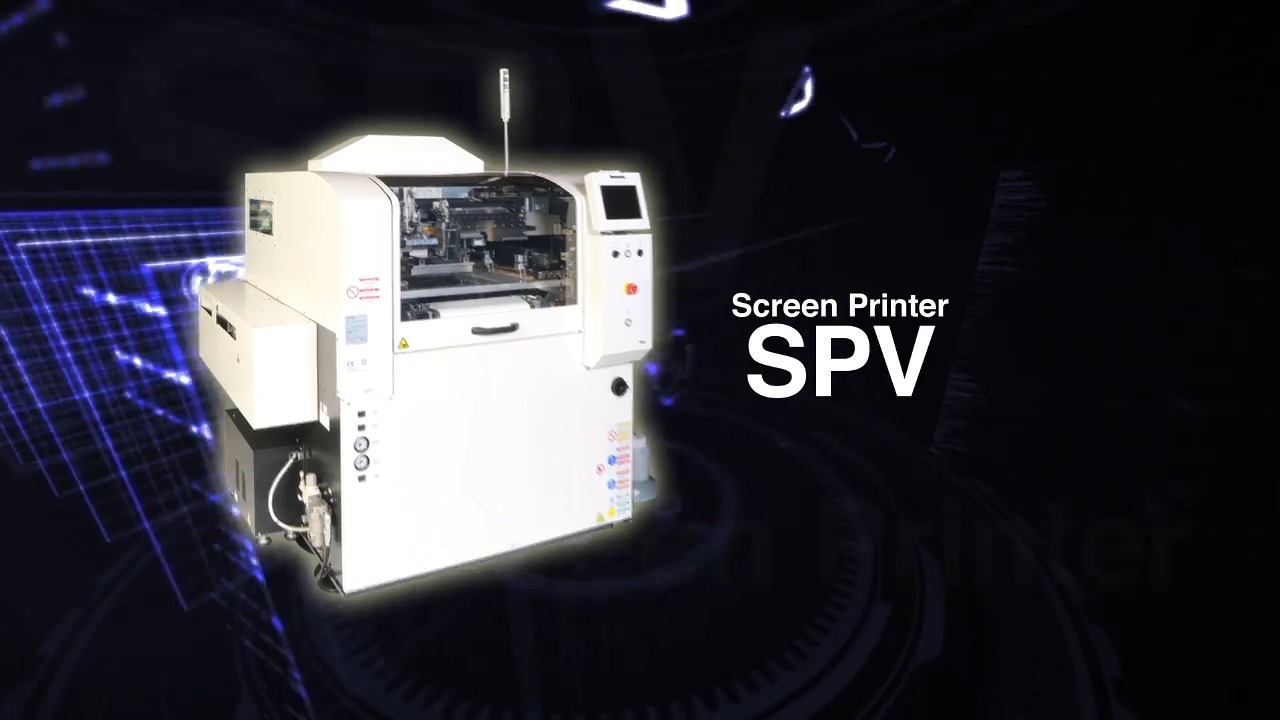

Screen Printer SPV

Key features and functions

- Printing cycle time of 10 seconds including transport, recognition, and cleaning each time

- High print quality

- Printing process matched to the production configuration and adaptable to various layouts

Features

Printer with built-in PCB sorting function to realize ultra-high speed tact time

Ultra high-speed tact: This screen-printer achieves a cycle time of 10 seconds. Built-in PCB sorting function enables the machine to accommodate various line layouts of customers.

Problems this product contributes to

High Productivity

Various functions utilizing dual lanes enable highly efficient production.

High Printing Quality

Various functions and line solutions realize high quality printing.

Support for Various layouts

Printing processes that match the production style can be realized, and various layouts can be accommodated.

High Productivity

High speed printing (10 sec/sheet) and stable printing

Cycle time of 10 seconds per sheet is realized, achieving both high-speed printing and stable quality with each cleaning.

Automatic solder supply (option)

Two solder pots allow continuous operation for 4 hours.

High Printing Quality

Mask adsorption plate separation

Even with a mask with loose tension, the mask is adhered to the PCB by adsorbing the mask. Also, by removing the mask from the stencil while it is still adsorbed, the mask is removed from the stencil uniformly and stable quality can be maintained.

Hybrid PCB adsorption

Air flow is generated from the top to the bottom of the mask to improve solder release.

M2M line solution (APC-FB) (option)

Analyzes the measured data of solder inspection and corrects the print position (X, Y, θ).

Support for Various layouts

Built-in PCB sorting function

PCB sorting is possible without the traverser/sorting conveyor required for dual printing press installations.

Transformation Functions

Various production styles can be accommodated by combining sorting conveyors and equipment layouts.

Product specification

※1 The PCB replacement time depends on the equipment of the preceding and subsequent processes, the PCB size, the use of the upper PCB presser, etc.

※2 Please refer to the specification manual for mask specifications.

※ *The contents above are standard specifications. Please contact us for details as it may differ depending on usage conditions.

Exhibition and Seminar Information

Information on current seminars and exhibitions is compiled and posted here. Information on past seminars and exhibitions is also available.

Custom Service

Line simulation

Tact simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components

Maintenance solution

To ensure that our mounting machines can be reliably used by our customers for many years after delivery, we not only maintain the machines, but also continue to support our customers throughout the life span of the machines, reducing production loss, stabilizing operation and improving work efficiency.