Welding Power Source Integrated Robots

TAWERS WGIII/WGHIII

Overview

Super Active TAWERS High End model

Key functions

-

Contributes to productivity improvement with high-speed welding + ultra-low spatter

-

Reduces Max. 99% spatter (compared with conventional)

-

Supports welding of high-tensile strength steel plates, etc., which are becoming thinner and thinner

-

Realizes high-quality welding of aluminum

-

Performs high-speed welding with high current 450 A

TAWERS WG III/WGH III Standard

Key functions

-

Reduces spatter with CO2 welding

-

Reduces spatter significantly during MAG welding of thin plates

-

Realizes high-speed pulse welding

-

Enables easy setting of welding parameters

Super Active TAWERS

Contributes to productivity improvement with high-speed welding + ultra-low spatter

Spatter generation amount

Reduces by Max. 99%

* Comparison with full digital welding machine (Panasonic data)

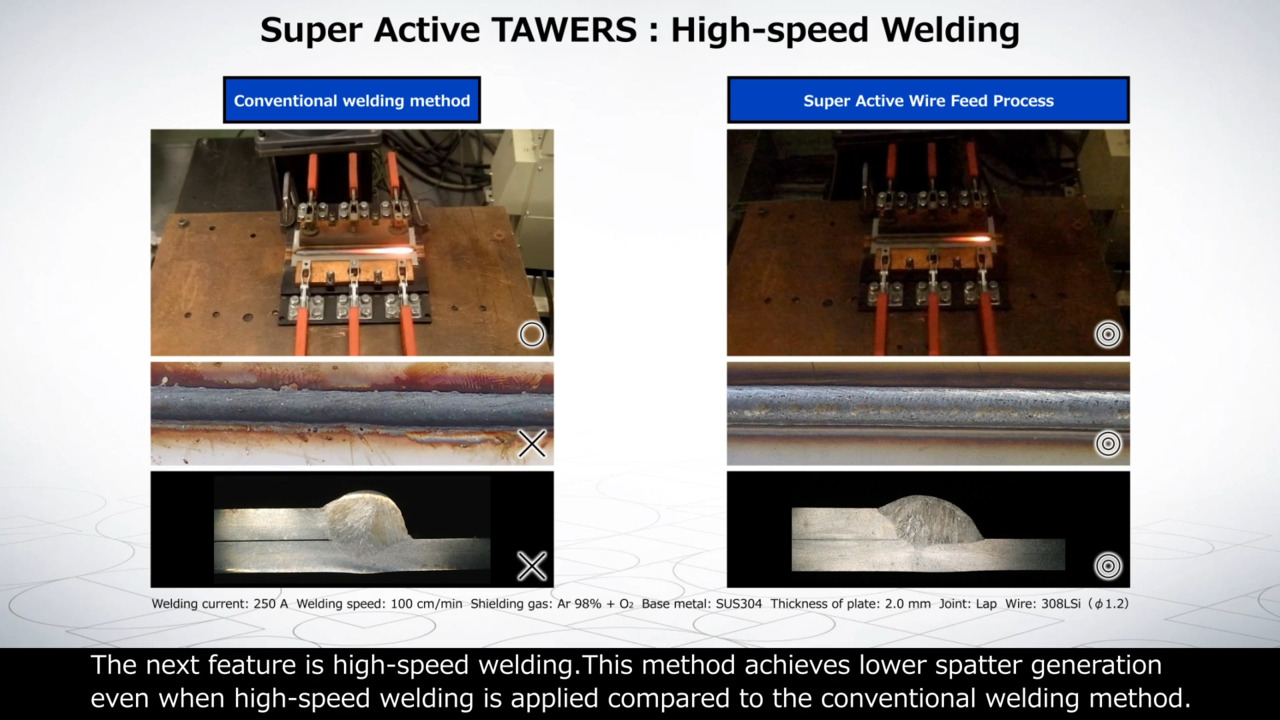

“Super Active TAWERS” is a welding robot that combines the welding power source integrated robot “TAWERS WG III/WGH III” with the “Super Active Wire Feed Process,” a high-precision wire feeding method, to achieve high-speed welding while significantly reducing the amount of spatter generated.

Mild steel SPCC

Joint lap, Gas CO2, Plate thickness t: 3.2 mm

Welding current: 320 A, Welding speed: 110 cm/min

Reduction for tact time Before→After

High-speed welding more than twice as fast is realized.

Reduces man-hours for spatter removal: Before→After

Even at 300 A, ultra-low spatter welding reduces spatter and man-hours required to remove spatter.

Supports welding of high-tensile strength steel plates, etc., which are becoming thinner and thinner

HBC (Heat Balance Control) process supports welding of high-tensile steel plates that are becoming thinner.

HBC process introduction: Before→After

Low heat input control significantly increases condition tolerances (welding speed and gap tolerance). Prevents burn through.

High tensile steel (980 MPa)

Joint lap, Gas MAG, Plate thickness t: 0.8 mm

Welding current: 150 A, Welding speed: 100 cm/min

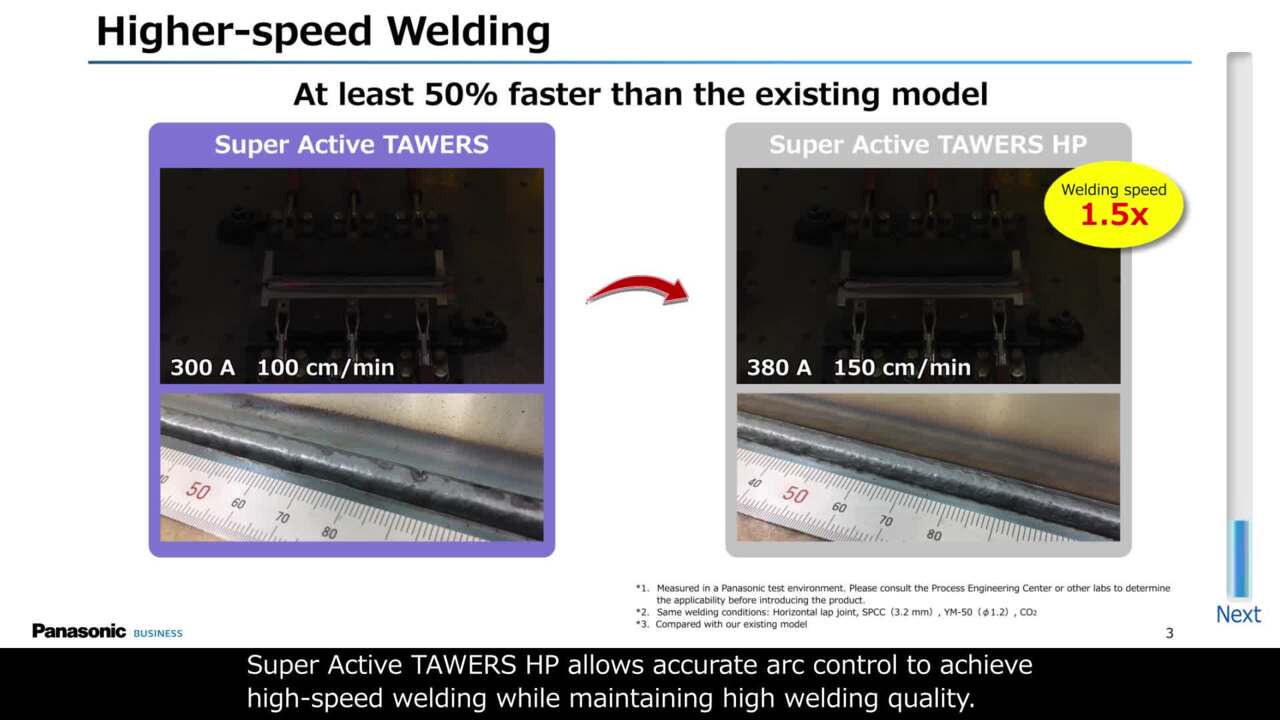

High-speed and medium-thick plate welding of high power 450 A

“Super Active TAWERS HP” is 50% faster than Super Active TAWERS and can reduce spatter by more than 60% even at 400 A.

Mild steel SPCC

Joint vertical lap, Gas CO2, Plate thickness t: 1.6 mm

Welding current: 380 A

Welding speed: 260 cm/min (30° downward)

Wire YM-50 (ϕ1.2)

Mild steel SPCC

Joint, Downward facing fillet, Gas CO2, Plate thickness t: 9.0 mm

Welding current: 320 A, Wire YM-50(Φ1.2)

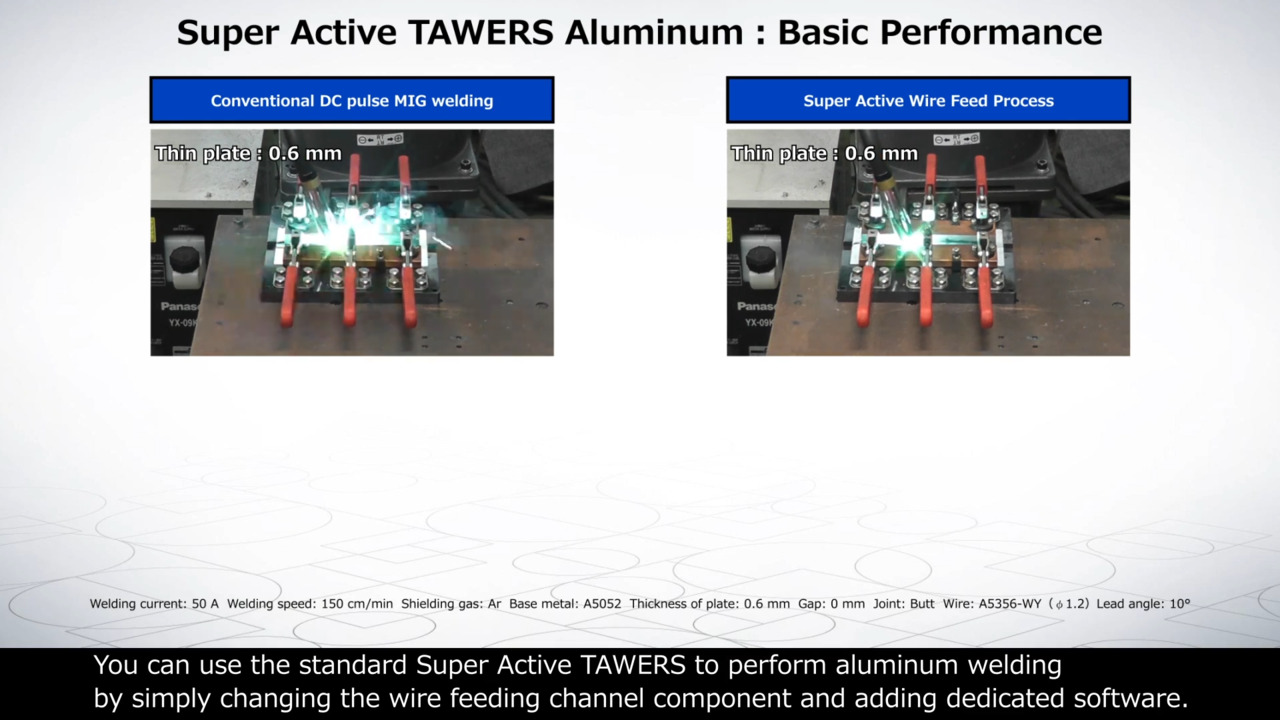

Realizes high-quality welding of aluminum

The ultra-low spatter performance of S-AWP, which has been proven on mild steel, has been extended to aluminum. Since it supports a wide current range of 40 A to 180 A, high-speed welding and expansion of applicable plate thickness are possible.

Joint, T joint, Plate thickness t: 3.0 mm

Welding current: 155 A, Welding speed: 60 cm/min

Effective for welding thin aluminum plates.

Aluminum A5052

Joint, Butt, Plate thickness t: 0.6 mm

Welding current: 50 A, Welding speed: 150 cm/min

Reduces spatter and blowholes during welding of zinc-coated steel

General welding wire (solid ɸ1.2) can be used. Applicable to MAG welding as well as CO2.

It also works well with a wide range of weld volumes.

CO2 Gas: 45 to 190 g/m2

MAG Gas(80:20) 45 to 60 g/m2

MAG Gas(90:10) 45 to 60 g/m2

250 A 80 cm/min

Zinc-coated steel sheet, Plate thickness 2.3 mm, Lap joint

What is the Super Active Wire Feed Process?

High-precision feed control where the welding wire is fed continuously with a back and forth motion.

Spatter reduction by stable short-arc cycle.

TAWERS WGⅢ/WGHⅢ

Reduces spatter with CO2 welding

Metal transfer stabilization (MTS) control suppresses CO2-specific spatter.

Spatter is reduced by up to 75% in the 150 A range compared to a full digital welding machine (350GB2) while maintaining the stable pan-bottom shaped penetration achieved by CO2 welding.

Reduces spatter significantly during MAG welding of thin plates

Welding waveform control technology achieves low spatter in short-circuit transfer range. Spatter is reduced by up to 90% in the 150 A range compared to a full digital welding machine (350GB2).

Realizes high-speed pulse welding [HD-Pulse]

Short arc length and narrow arc width prevents undercuts caused by insufficient deposition during high-speed welding.

Dip transfer enables lower heat input than droplet transfer. Gap tolerance is improved.

Welding parameters can be set easily [Welding Navigation]

Since extensive welding parameters database accumulated through years of experience is preinstalled, welding parameters can be checked and set with the teach pendant easily. Leg length and welding speed can be adjusted from automatically set conditions and current/voltage conditions are calculated automatically according to the changes made. Therefore, time required for setting welding parameters can be reduced.

Select weld joint. The figure changes according to the joint.

Then, all you have to do is enter the plate thickness.

In addition, leg length and welding speed can also be adjusted. Current/voltage conditions are automatically calculated based on the changes made.

Quality improvement at weld start and end points and high-speed processing is possible

The robot lifts up the welding torch quickly at the start and end of the weld in conjunction with the welding waveform and wire feed control.

High-speed TIG welding - Realizes high fusion welding [TAWERS TIG]

An excellent arc start allows improved welding quality and reduced takt time. High frequency start and touch start can be selected. Proximity of electrode and filler wire increases wire heating effect.

Stable filler feeding is achieved with a curved neck, which is effective in improving weld quality and limiting deviation of aiming point.

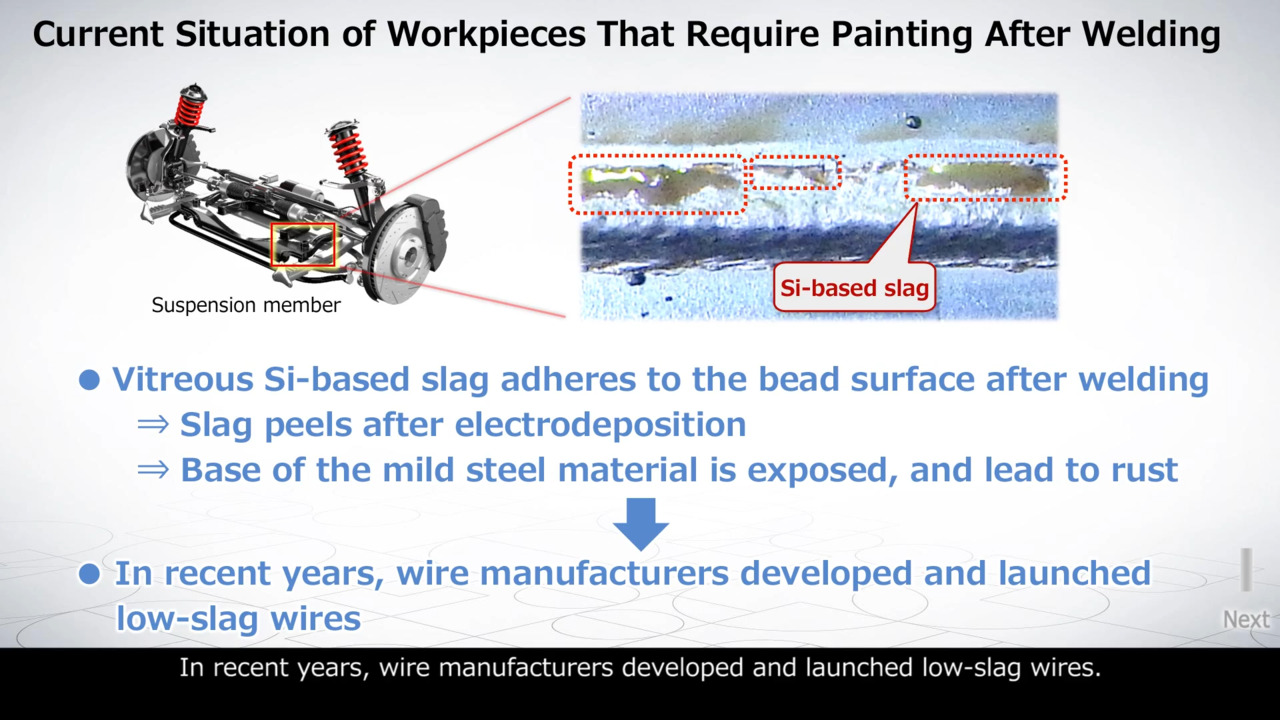

Slag Solution

Prevents paint peeling due to slag peeling and ensures high quality.

Slag generation is a sign of sound welding results

- Arc heat decomposes CO2 into CO and O

- Si and Mn present in the wire combines with O inside the molten metal

- SiO2 or MnO (slug) are generated

* Steel is also a source of O2.

* Slug is an evidence of a sound welding result, as residual O can cause blowholes and pits.

Since slag causes rusting, measures are necessary

If slag generated during welding remains on the surface of the beads, rust may occur because electrodeposition coating cannot be applied.

Therefore, a welding method that does not leave slag on the surface of the beads is required.

Solutions for various wires and welding methods

slag

We offer solutions by combining options optimized for the wires of each company with TAWERS HD Pulse (MAG) or Super Active TAWERS (CO2).

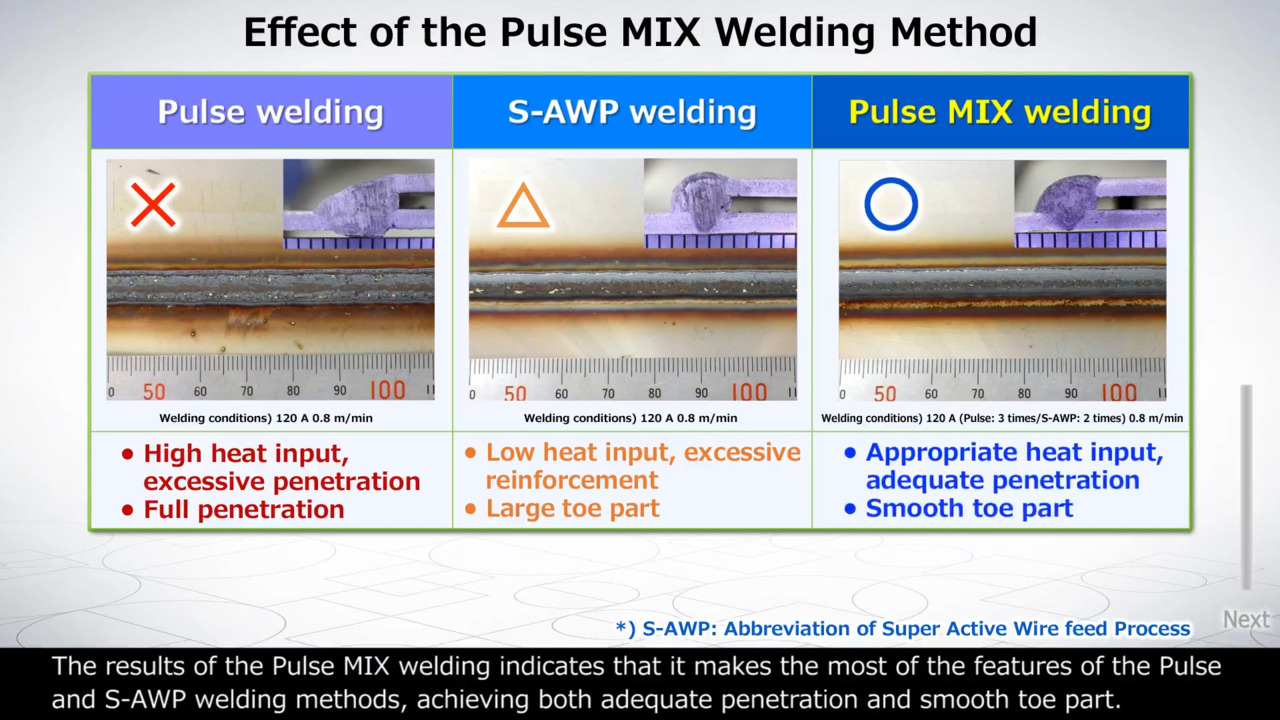

Solution for welding thin plates with gaps: Pulse MIX welding method

What is the pulse MIX welding method?

This is a welding method that alternately outputs pulse welding with high heat input and Super Active (S-AWP) welding with low heat input to improve the tolerance when welding thin plates with gaps.

Mechanism

When crossing gaps, normal pulse welding tends to cause high heat input and excessive penetration, while normal S-AWP welding tends to cause low heat input and excess weld reinforcement height. The Pulse MIX welding method combines these 2 welding methods to ensure proper penetration while reducing thermal distortion, increasing gap resistance, and reducing burn through.

Key Specifications and Options

Mild steel/Stainless steel (CO2/MAG/MIG)

S-AWP: Super Active Wire Feed Process

HBC: Heat Balance Control

OP: Optiion

| Series | Welding method and welding power source | Reated current | CO2 | MAG/MIG | Pulse MAG/MIG | S-AWP CO2 | S-AWP MAG/MIG | HBC | Zi-Tech | TAWERS fusion function |

|---|---|---|---|---|---|---|---|---|---|---|

| TAWERS (TS/TM/TL) | Super Active TAWERS |

350 A / 450 A (HP) |

◯ *1 | ◯ *2 | ◯ *3 | ◯ | ◯ | OP | OP | ◯ *4 |

| TAWERS | 350 A | ◯ *1 | ◯ *2 | ◯ *3 | OP | OP | OP | OP | ◯ *4 | |

| For medium and thick plates TAWERS |

450 A | ◯ *1 | ◯ *2 | ◯ *3 | - | - | - | - | ◯ *4 |

*1 Compatible with MTS-CO2 *2 Compatible with SP-MAG *3 Compatible with HD-Pulse *4 Lift Start, Lift End, etc.

Aluminum (MIG)

| Series | Welding method and welding power source | Rated current | MIG | Pulse MIG | AC MIG *1 | S-AWP MIG | HBC | TAWERS fusion function |

|---|---|---|---|---|---|---|---|---|

| TAWERS (TS/TM/TL) | Super Active TAWERS Aluminum |

350 A | ◯ | ◯ | OP | ◯ | - | ◯ *2 |

| TAWERS Pull AC-MIG |

350 A | ◯ | ◯ | ◯ | OP | - | ◯ *2 |

*1 AC MIG system cannot be used in combination with S-AWP Aluminum function. *2 Lift Start, Lift End, etc.

TIG

| Series | Welding method and welding power source | Rated current | DC | AC | Arc start |

|---|---|---|---|---|---|

| TAWERS (TS/TM/TL) | TAWERS-TIG | 350 A | ◯ *1 | - | High frequency |

| 350 A | ◯ *1 | - | Touch |

*1 Compatible with high-speed TIG

Specifications

External dimensions

■ Controller external dimensions

■ Teach pendant external dimensions

Controller standard specifications

| Name | WG III (including power unit) | WGH III (including power unit) |

|---|---|---|

| External dimensions(mm)* | (W)553×(D)550×(H)1181 | (W)553×(D)550×(H)1407 |

| Mass | 135 kg | 171 kg |

| Memory capacity | 40 000 points | |

| Position cotrol method | Software servo system | |

| External memory I/F | TP : SD card slot ×1、USB×2 | |

| Number of control axes | Simultaneous 6 axes (max. 27 axes) | |

| Input/output signal | Dedicated signal: Input: 6 points, Output: 8 points, General signal: Input: 40 points, Output: 40 points Maximum input/output (option): Input 2048 points, Output: 2048 points |

|

| Input power supply | Three-phase 200/220 V±20 V, 22 kVA (Maximum current with servo ON: 246 A/5.6 ms) |

Three-phase 200/220 V±20 V、30.5 kVA 50/60 Hz common use (Maximum current with servo ON: 246 A/5.6 ms) |

| Input cable | 14 mm2 (AWG 6) or more | 14 mm2 (AWG 6) or more |

| Ground cable | 14 mm2 (AWG 6) or more | 14 mm2 (AWG 6) or more |

| Applicable welding method | CO2/MAG/Stainless steel MIG Pulse MAG/Stainless steel pulse MIG |

|

| Output current | DC 30 A to 350 A | DC 30 A to 450 A |

| Outputvoltage | DC 12 V to 36 V | DC 12 V to 42 V |

| Rated duty cycle (10-minute cycle) |

CO2/MAG/Stainless steel MIG 80 % Pulse MAG/Stainless steel pulse MIG 60% |

100% |

* Teach pendant and connection cables are not included.

Note: For details on power supply connection, refer to wiring of primary power supply in the instruction manual of the robot controller for arc welding.

Manipulators

Space saving & high payload

TS series

Standard type

TM series

Long arm & high payload

TL series

Medium type multi-purpose robot

LA-1800

Related Products

Simple robot teaching system

Easy and effortless teaching with VR technology

VRPS

Integrated welding management system

IoT for the entire line

iWNB

IoT for the entire line

Equipped with AI function - Fully automated visual inspection

Bead Eye

Genuine parts and other peripheral applications

Support

Global network

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website for Panasonic Shoyokai

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.