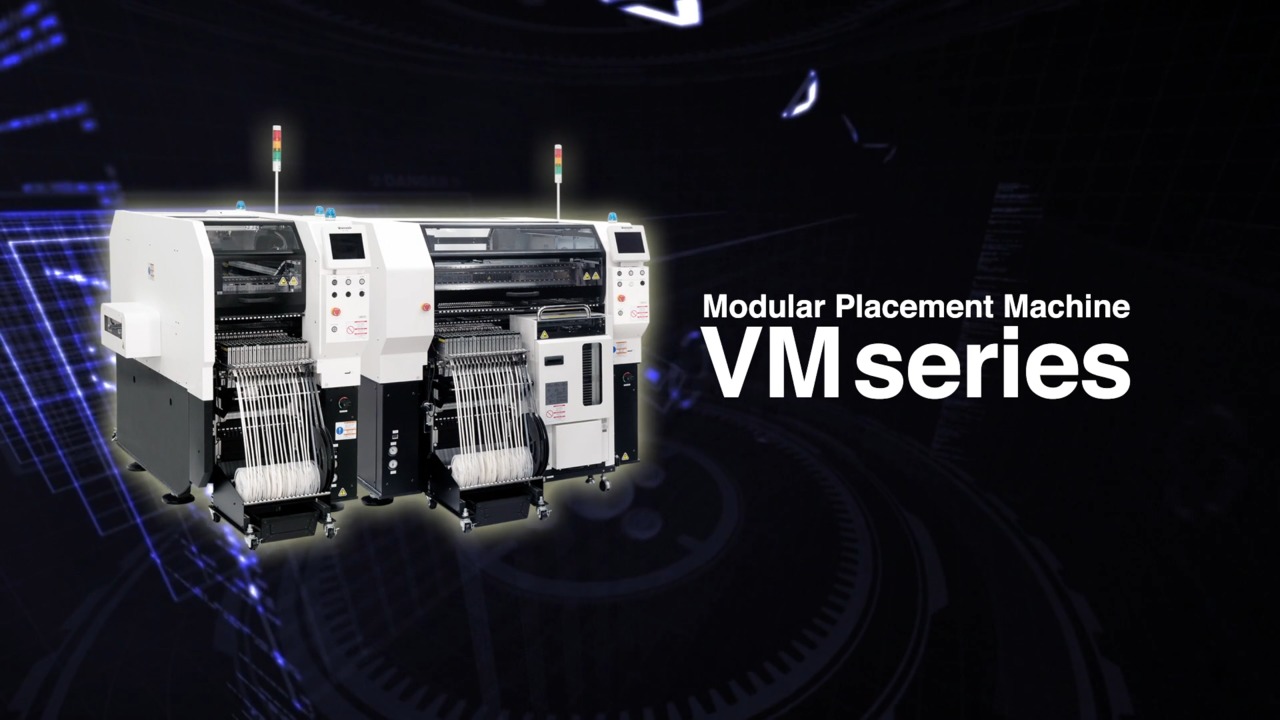

Modular Placement Machine VM Series

Modular Placement Machine VM Series

A compact, high-performance entry-level model that can flexibly handle everything from high-speed production to production of various kinds of products in small quantities and prototype production, with a wide range of variations.

VM101

- High productivity with ±30 μm placement accuracy

- Max. speed: 42,000 cph

- Maximum component type: 80-component type / 8 mm tape equivalent

- Placement head select from 16, 8 and 4-nozzle head (NH)

- Feeder specifications: Fixed feeder, feeder cart, tray feeder

VM102

- Highly versatile 1-head solution

- Max. speed: 32,100 cph

- Maximum component type: 160-component type / 8 mm tape equivalent

- Placement head and 14-nozzle head (NH)

- Feeder specifications: Fixed feeder, feeder cart, tray feeder

Features and Benefits of “Modular Placement Machine VM Series”

Flexibly adapting to your production style with a wide range of variations

From chip components (0402) to large odd-form components

Component adaptability area

VM101

Selects the optimum placement head to match the PCB

Equipped with NPM X series head

Lightweight 16NH V2

42,000 cph/chip

Height: H≦3 mm

Placement accuracy: ±30 μm/chip

Lightweight 8NH

22,500 cph/chip

Height: H≦12 mm

Placement accuracy:

±30 μm/chip

±30 μm/QFP □12 mm ~

±50 μm/QFP ~12 mm

4NH

8,200 cph/chip

Height: H≦30 mm

Placement accuracy: ±30 μm/QFP

VM102

One single head with 14 nozzle heads

A single head can pick up up to 14 components/turn (components up to □14 mm)

14NH

32,100 cph

Height: H ≦ 28 mm *Use specific nozzle

Placement accuracy:

±40 μm/chip

±50 μm/QFP ~ □12 mm

±30 μm/QFP □12 mm~

Introduction video of “Modular Placement Machine VM Series”

Exhibition and Seminar Information

Information on current seminars and exhibitions is compiled and posted here. Information on past seminars and exhibitions is also available.

Custom Service

Line simulation

Tact simulation can be performed according to the mounted components and supply form.

Mounting feasibility study (nozzle selection)

We propose the optimum nozzle for the mounted components

Maintenance solution

To ensure that our mounting machines can be reliably used by our customers for many years after delivery, we not only maintain the machines, but also continue to support our customers throughout the life span of the machines, reducing production loss, stabilizing operation and improving work efficiency.