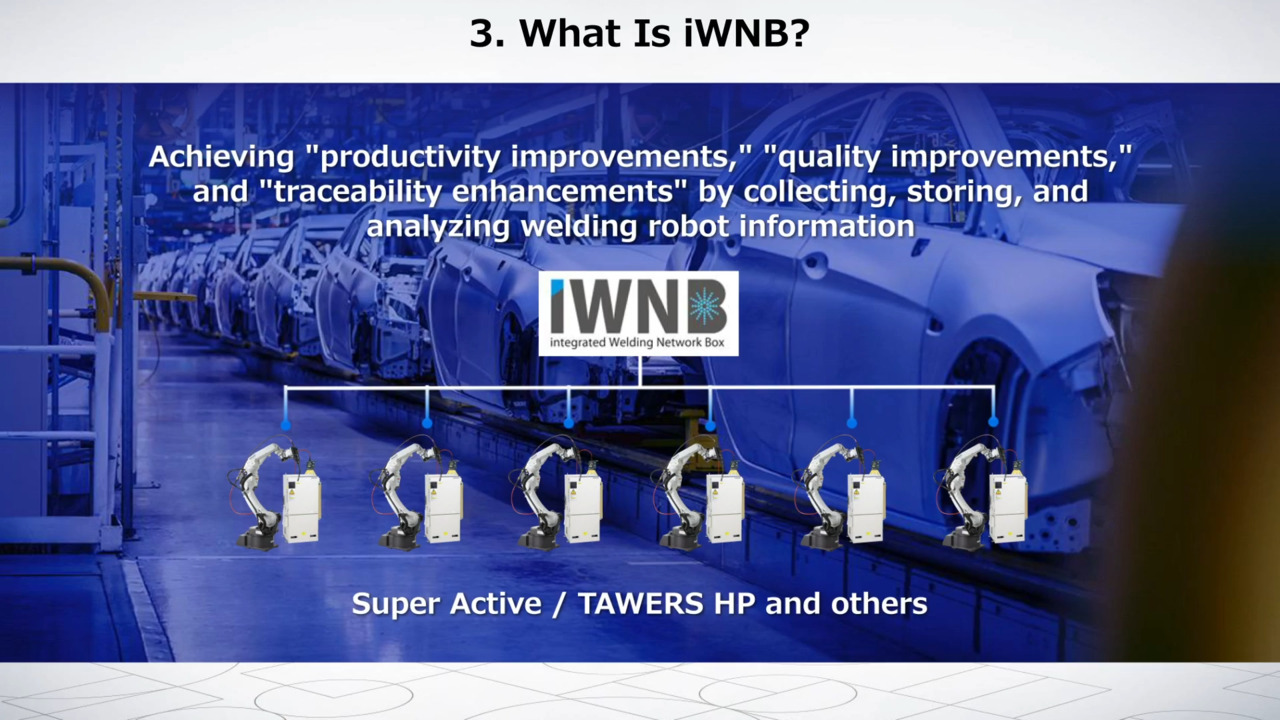

iWNB (Integrated Welding Management System) for Robots

Overview of iWNB (Integrated Welding Management System)

Although our customer’s issues are different, iWNB makes proposals for stable production and productivity improvement through “Digitalization” and “Visualization” of equipment operation status and quality information.

* Up to 32 robots can be connected to iWNB PC through LAN

Features of iWNB

| No. | Category | Items | Contents |

|---|---|---|---|

| 1 | Management Index | KPI | Check the Key Performance Indicator (KPI). |

| 2 | OEE | Check the Overall Equipment Effectiveness (OEE). | |

| 3 | Operation Information | Operation status | Check current operation status. |

| 4 | Operation record | Check past operation records. | |

| 5 | Production Information | Production status | Check production status of the day. |

| 6 | Production results | Check past production results. | |

| 7 | Average cycle time | Check cycle time per work. | |

| 8 | Cost performance | Check the cost performance of electric, wire, and gas expenses per work. | |

| 9 | Production plan | Input the production plan. | |

| 10 | Traceability | Welding result list | Check the program list, welding errors, welding results and weld line information. |

| 11 | Error History | Error list | Check the list of occurred errors. |

| 12 | Short time breakdown ranking | Display the short time breakdown ranking from the most frequent to the least. | |

| 13 | Long time breakdown ranking | Display the long time breakdown ranking from the longest stop time to the least. | |

| 14 | Troubleshooting | Display the sheet of troubleshooting for errors. | |

| 15 | Maintenance | Load factor | Check the load factor of 6-axis robot motors. Set up the notification. |

| 16 | Feed motor current | Check the feed motor electric current. Set up the notification. | |

| 17 | Tip replacement timing | Estimate the tip wear from the degree of the output current drop. | |

| 18 | Maintenance history list | Input and check of the maintenance history list. |

- A “short time breakdown” is a frequently occurring stop although it has a short stop time (It is judged as a short time breakdown if the following is satisfied. Recovered date and time - Occurred date and time ≤ 10)

- A “long time breakdown” is a stop that has a long stop time (It is judged as a long time breakdown if the following is satisfied: Recovered date and time - Occurred date and time ≧ 30 minutes)

Customer Benefits

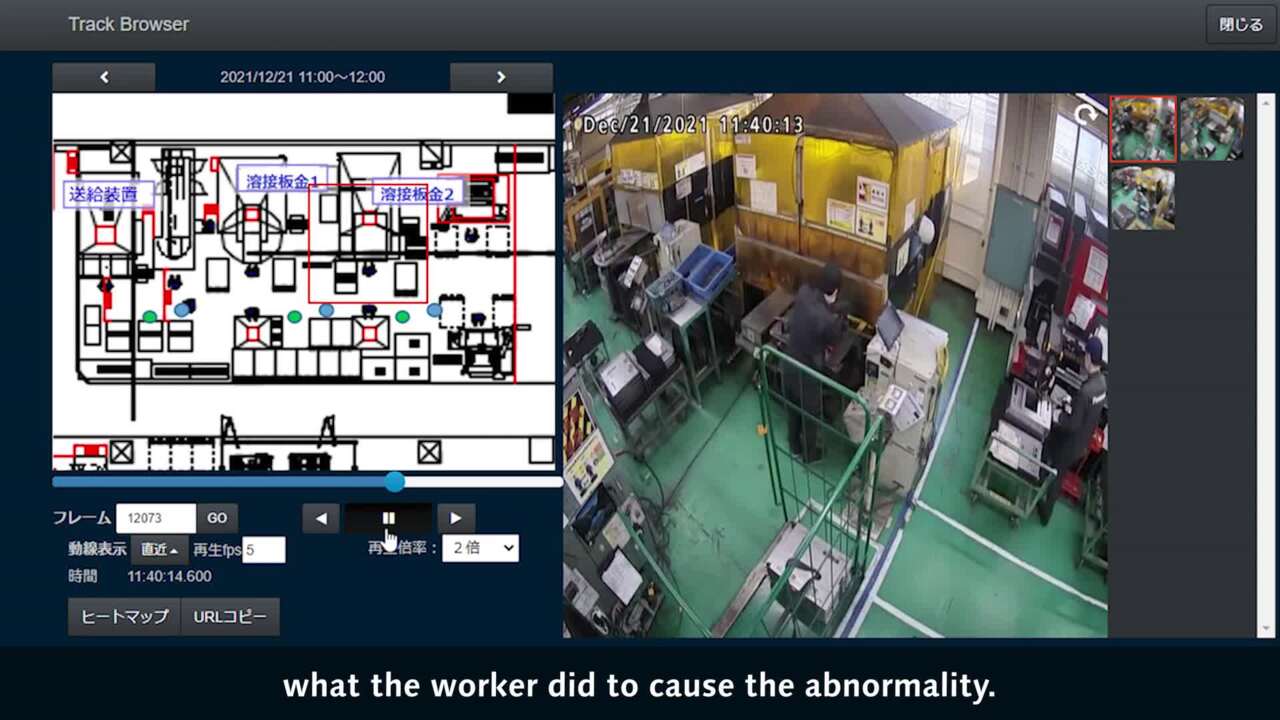

These are the specific examples of the benefits that we provide to our customers through iWNB.

Case studies of solving problems with iWNB (4:11 minutes)

System Configuration

“Visualization” by iWNB requires and 2. Robot License.

iWNB is a web application and can be accessed from a client PC browser.

【Benefits of web applications】

- Can be connected and checked anytime from a PC that is connected to the company network.

- No need to install software on the client PC, thus it saves labor on program distributions, etc.

- The operation response is mainly determined by the server performance, and does not significantly affect client performance.

* Customers have to prepare their network environment

Case Studies

Panasonic Kaga Factory

More details coming soon.

Precautions upon Purchase

Please make sure to read the precautions below before purchasing iWNB.

- iWNB supports Panasonic welding robot WG3 series, WGH3 series and G3 series only; it does not support robots from other manufacturers.。Please contact your nearest sales office for details

- iPlease contact your nearest sales office for the details on the retail price of iWNB, contract, operating environment and items to be prepared by the customer.