Case Studies of Solving Problems

Problem: Need to Weld Thin Plates without Burn-through

Problem: Need to weld thin plates without burn-through

Control of weld heat input when welding thin plates is difficult and burn-through is the biggest challenge. Heat Balance Control software solves this problem.

Problems faced by customers

■Need to perform gap welding on a thin plate without burn-through.

■Need to achieve good bead appearance

Super Active TAWERS+HBC(Heat Balance Control)Process Introduced for Thin Plate Welding

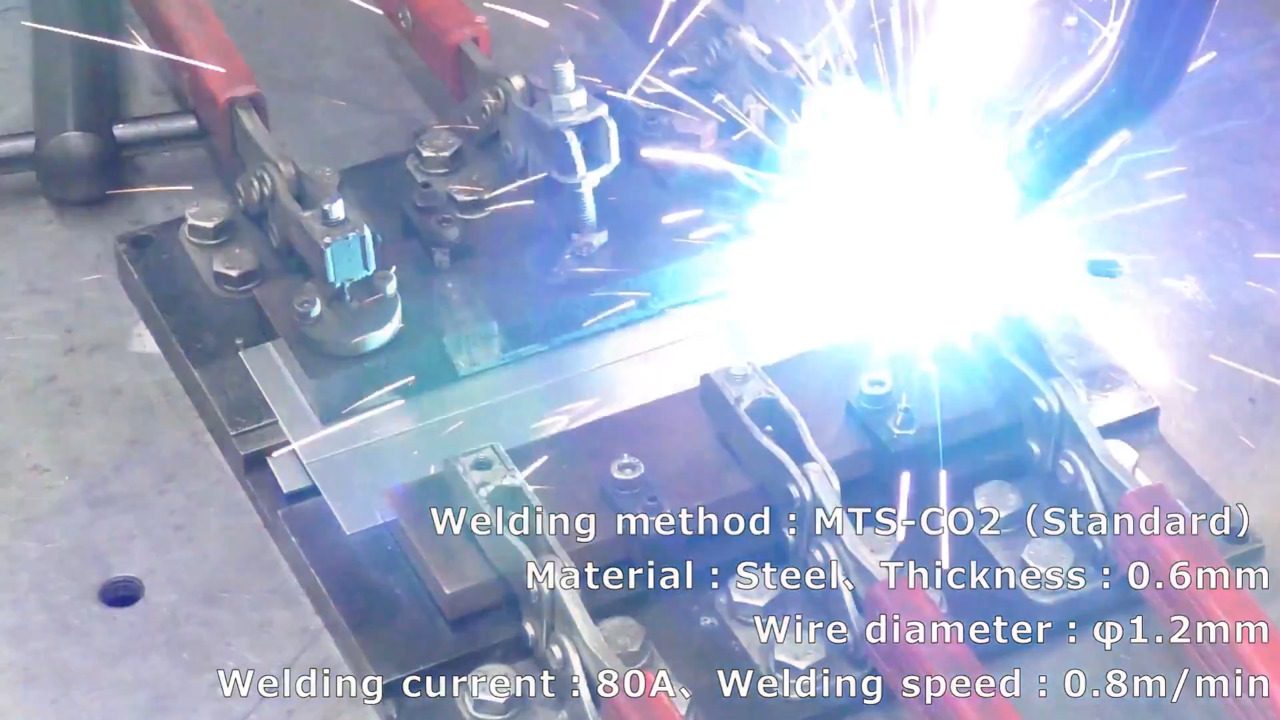

Standard CO2 welding (Click to enlarge)

Unstable beads due to burn-through

Video (Standard CO2 welding)

Welding method: MTS-CO2 (standard)

Base metal: Mild steel, Plate thickness: 0.6 mm, Wire diameter: ϕ1.2 mm.

Welding current: 80 A, Welding speed: 80 cm/min

Super Active TAWERS + HBC software can easily weld thin plates of 1.0 mm or less by fine control of heat input.

Super Active TAWERS+HBC (Heat Balance Control) Process Enables Thin Plate Welding

Low heat input control greatly expands condition margins (welding speed and gap margin). Prevents melting down.

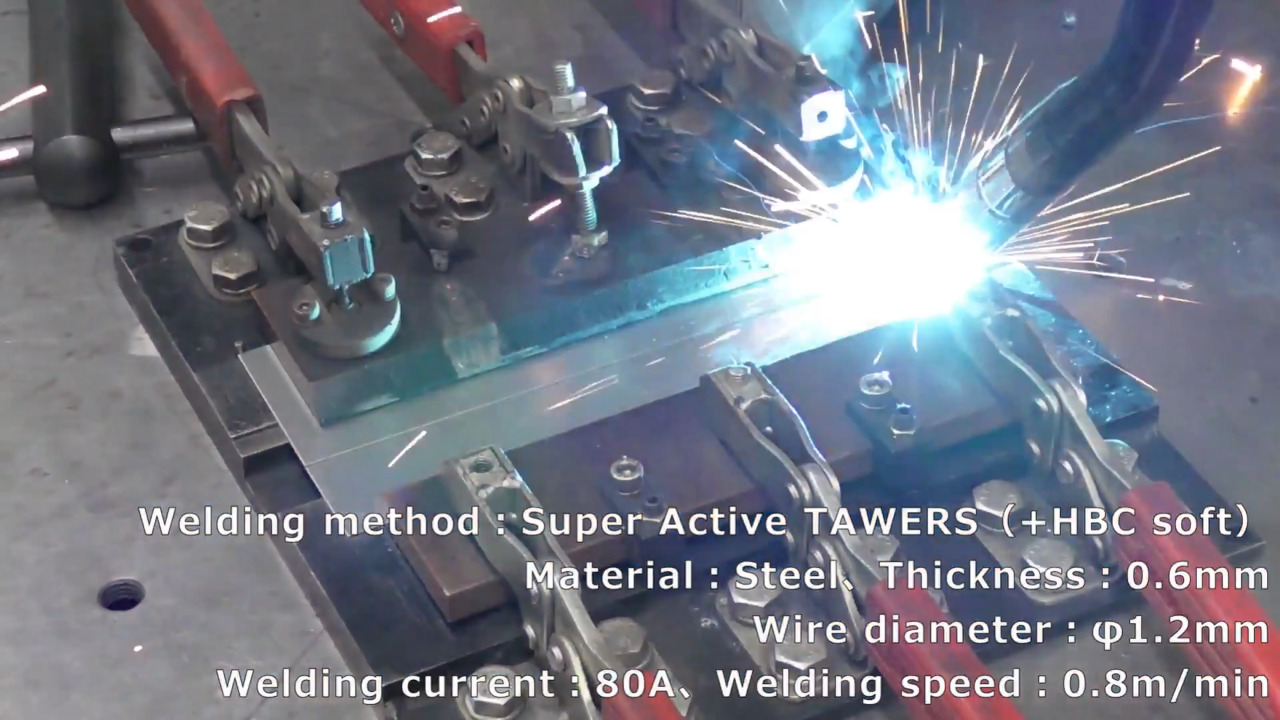

Super Active TAWERS + HBC Software (Click to enlarge)

Good beads without burn-through.

Video (Super Active TAWERS + HBC software)

Welding method: Super Active TAWERS (+ HBC software)

Base metal: Mild steel, Plate thickness: 0.6 mm, Wire diameter: ϕ1.2 mm.

Welding current: 80 A, Welding speed: 80 cm/min

Support

Global Network

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website for Panasonic Shoyokai

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.