Infrastructure Field - Automation

Infrastructure Field - Automation

This is a collection of case studies in the infrastructure field. System case studies for each part are available.

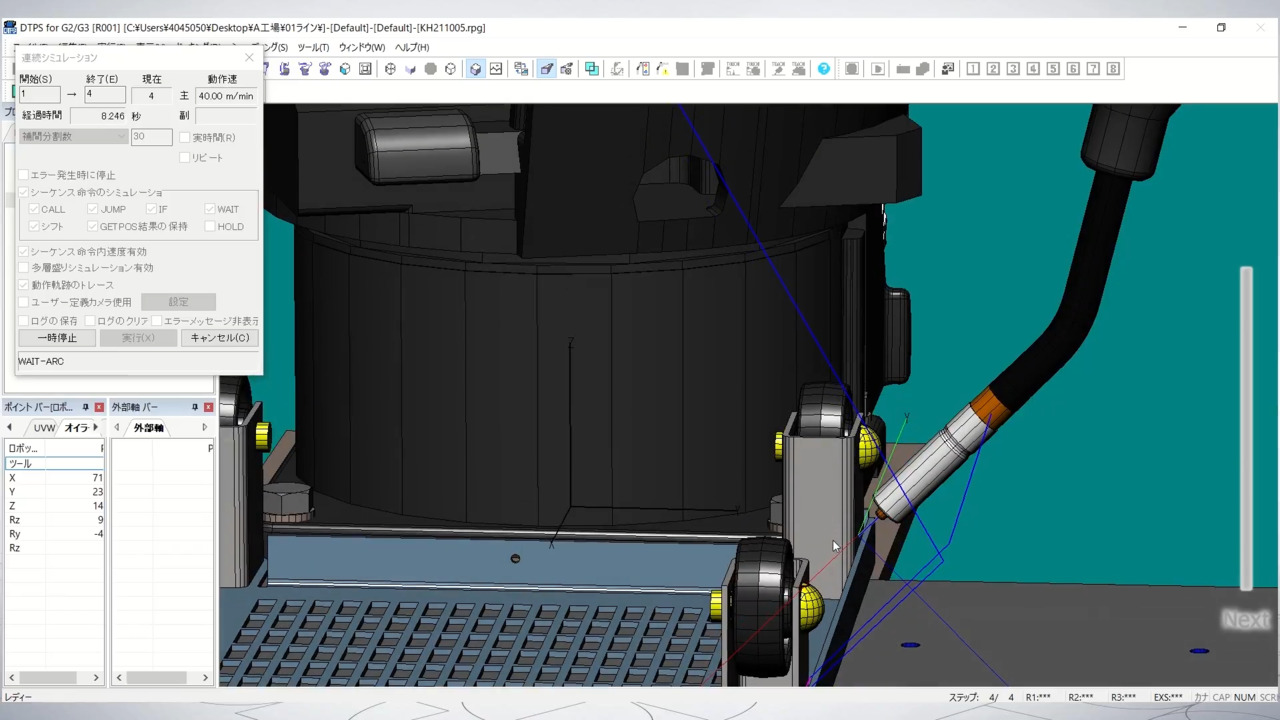

*The videos are created using DTPS III offline teaching and editing software

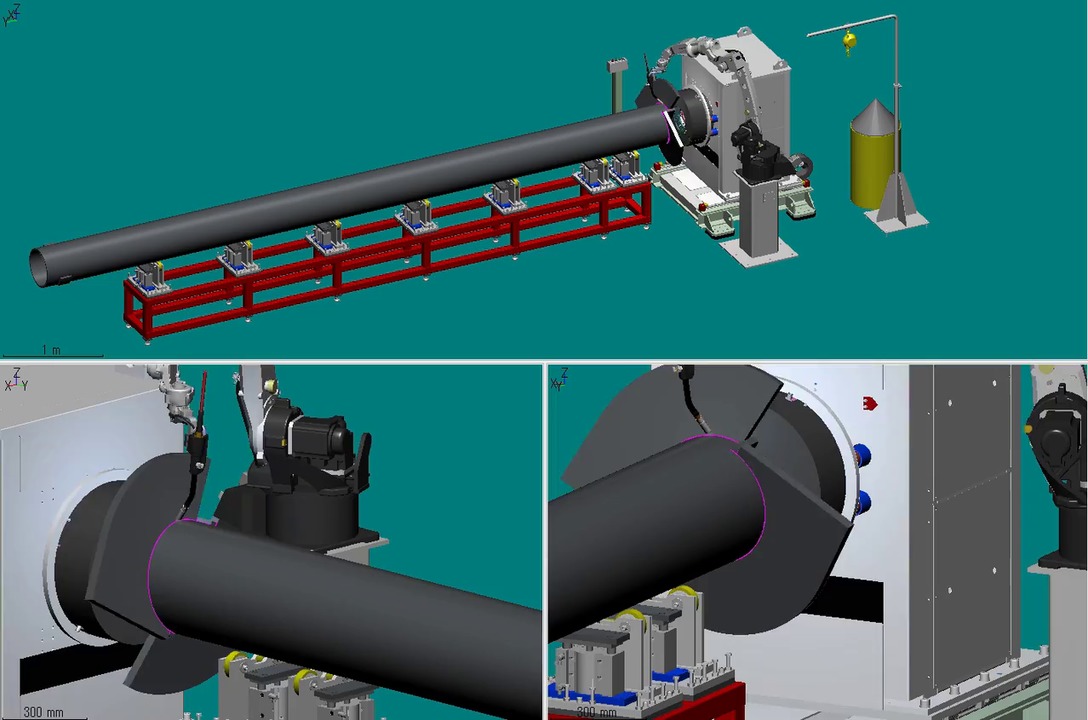

Steel pipe pile

A rotating jig to handle long workpieces.

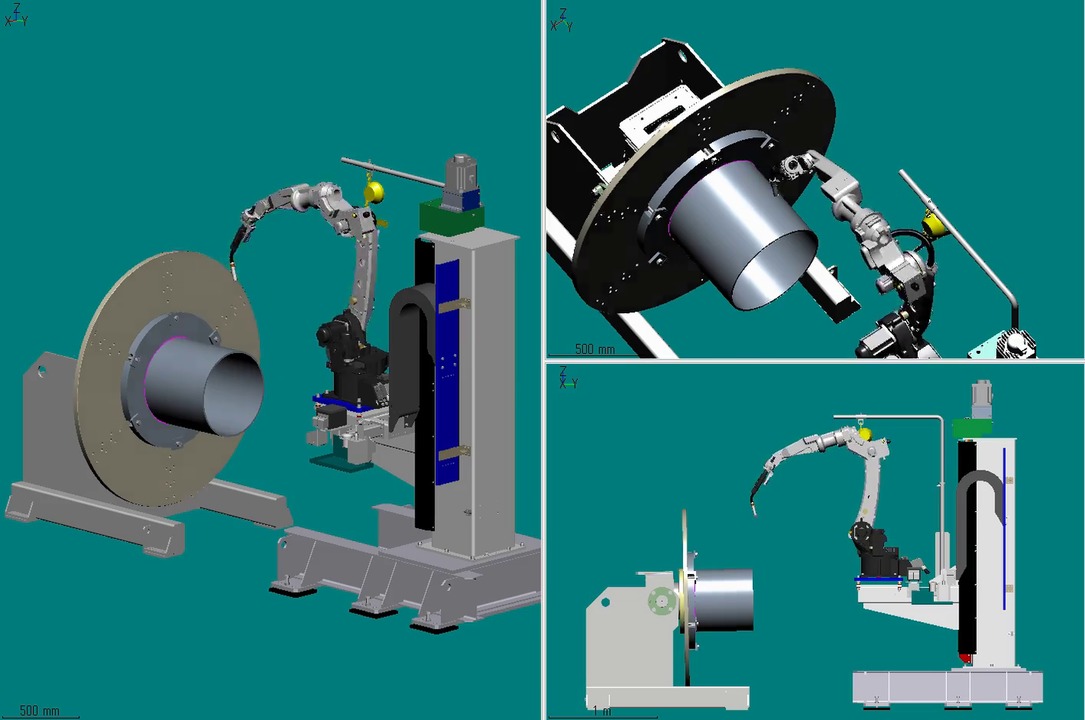

Large flange

The outside and inside of the flange can be welded with a highly general-purpose, double-sided, 2-axis welding positioner.

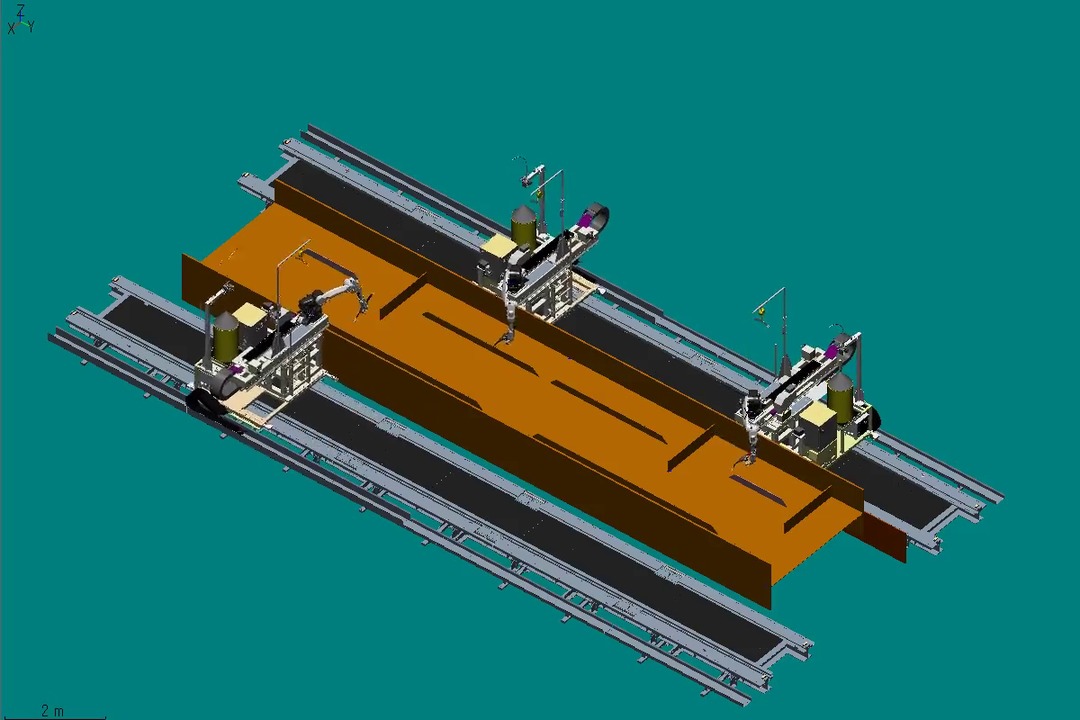

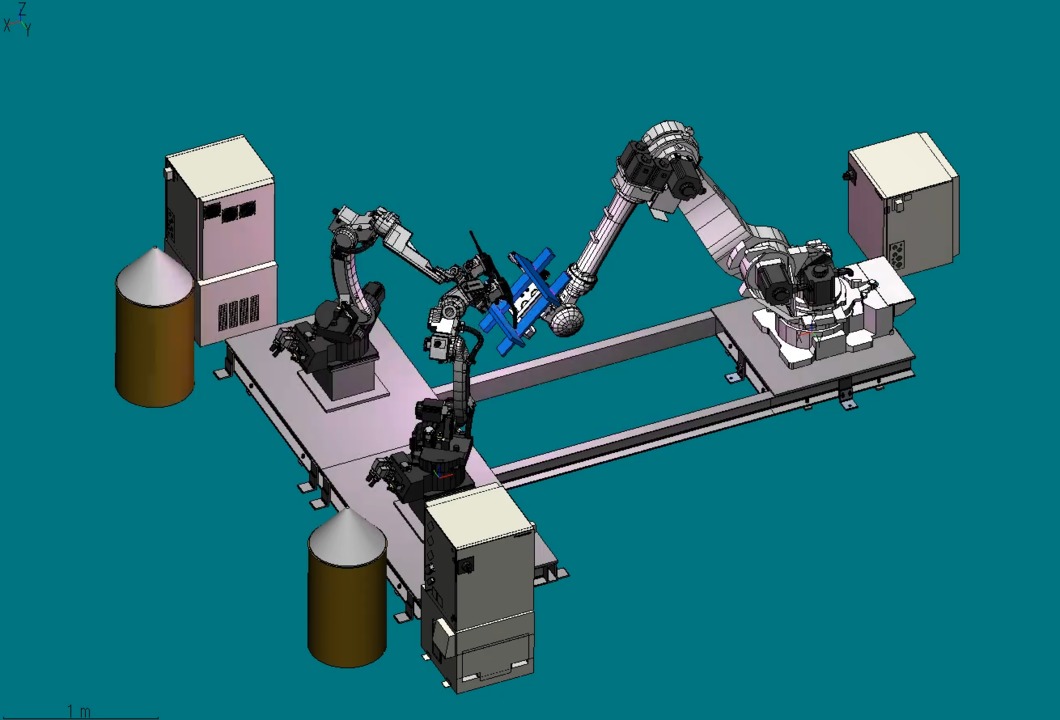

Bridge

Takt time can be reduced for large workpieces by using three robots and a slide mechanism

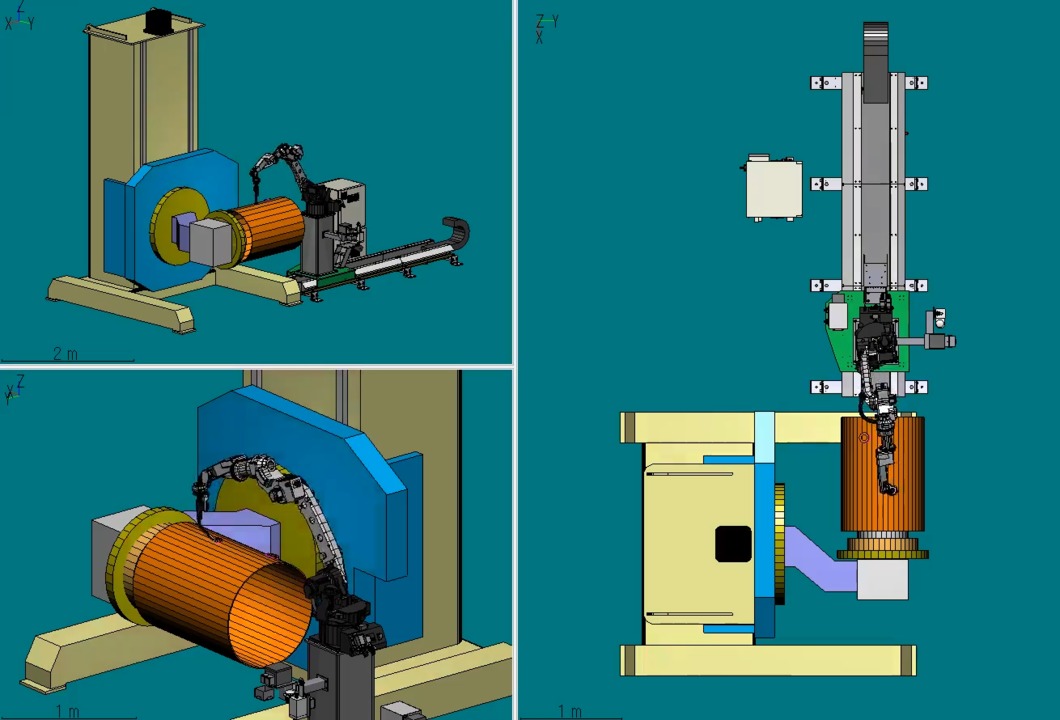

Chamber

Various workpiece shapes and sizes are accommodated by using an elevation-type welding positioner.

Small to medium components

A handling robot is used to hold the workpiece to achieve welding with a high degree of freedom through the coordinated operation of 3 units.

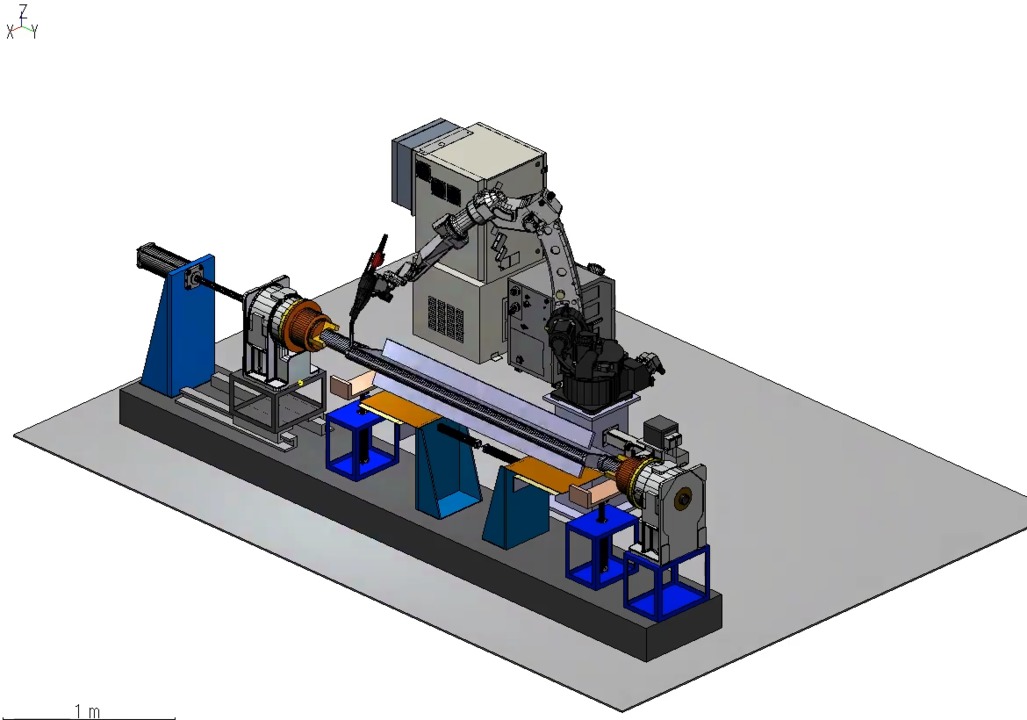

Long components

Front and back sides are welded in one program using a rotation-type welding positioner. Reduction of man-hours required for changeover can be realized.

Offline teaching and editing software DTPS III

This verification software can be used for various applications such as robot movement range, interference checks, optimal equipment layouts, and approximate takt trial calculations, etc., in virtual space on a PC. The software can also be used as a support tool during start-up of production sites.

Support

Global Network

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website for Panasonic Shoyokai

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.