Full Digital CO2/MAG/MIG Welding Machine

YD-400NE1

Overview

YD-400NE1

* In addition to this product (welding power source), a wire feeder, remote control unit, torch, and gas regulator are required for welding.

Key functions

- Significantly reduced spatter

-

Easy access to the necessary information

-

Wire feeder meticulously designed for ease of use

Issues

Achieving a high-quality finish like an expert

This model significantly reduces the amount of spatter compared to conventional models. High-quality welding is now possible in a wide current range.

Knowing when to perform maintenance

The Welding Concierge function displays operation instructions as well as points to check before welding operation on the LCD. Users can rest assured since they will be notified when they have to carry out maintenance.

Making the welding process visible

Welding Navigation selects the recommended welding conditions when parameters are input, including the workpiece material, plate thickness, and joint type. Even inexperienced users and those who have been away for a long time can set optimal welding conditions.

Strengths and Features

Significantly reduced spatter and stabilized welding performance

With its 100 kHz inverter, even lower spatter welding can be achieved compared to conventional models. Especially for aluminum welding, this model demonstrates high performance in response to requests, such as the need to achieve a beautiful bead appearance and increase the amount of penetration at the start of welding.

<Welding conditions>

Welding current: 220 A, Welding voltage: 21.6 V, Welding speed: 50 cm/min

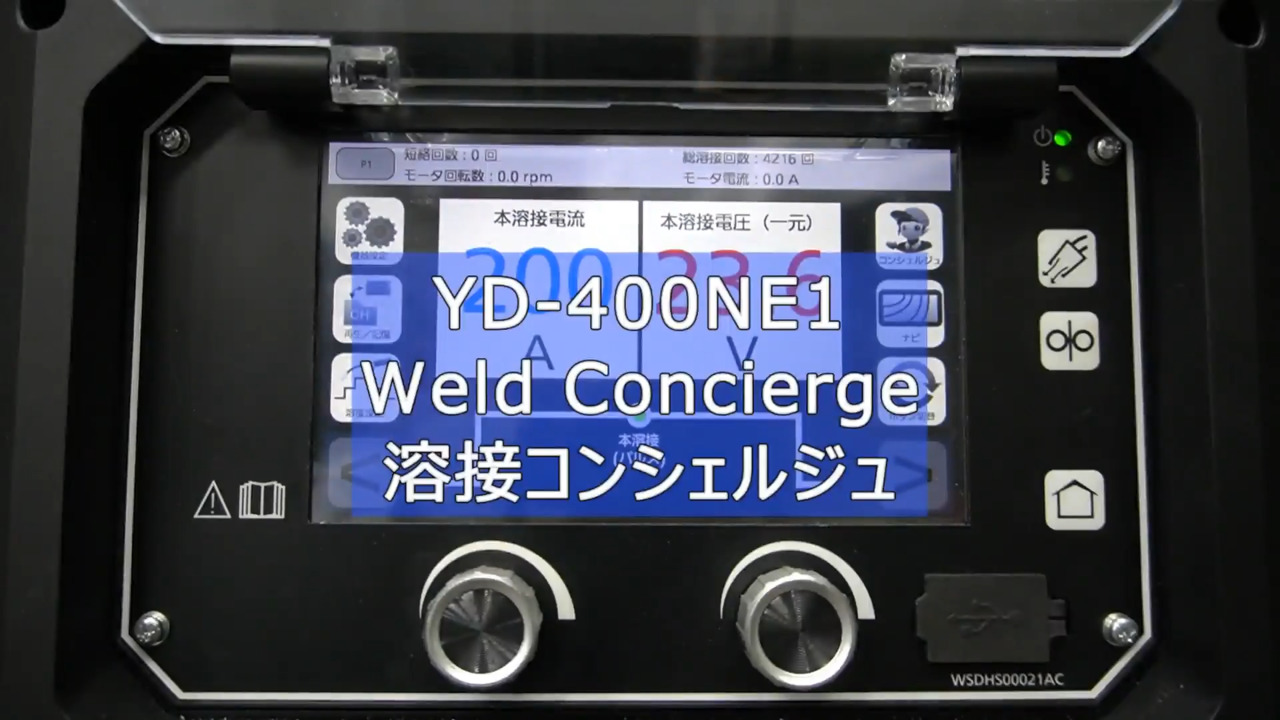

Welding Concierge allows users to easily access the necessary information

This function prompts workers to input frontline conditions and their requests such as the improvement of weld start quality on the LCD, facilitating welding parameter adjustments that require experience and expertise.

Since the configuration of the required devices and the specific procedures for wiring before starting welding are displayed on the LCD, even inexperienced users can safely operate this product.

The touch panel type color LCD monitor can display a wealth of information, thereby allowing users to check the configuration of the required devices and the specific procedures for wiring before starting welding.

Welding Navigation facilitates the setting of welding conditions

The main unit is equipped with Welding Navigation. The welding conditions are automatically determined by setting various conditions such as a joint shape and plate thickness on the LCD. Furthermore, the use of the Plate Thickness Command will enable users to set the welding conditions simply by entering the plate thickness.*

Even individuals who are not regularly engaged in welding or have limited experience can easily set welding conditions.

* Available for fillet welding of workpieces of the same thickness.

The new wire feeder combines safety and easy-to-use features

With a full cover structure that protects the drive and live parts, users can install the feed roller or replace the pressure roller without using any tools.

A lightweight aluminum frame (16 kg*) and a large handle for enhanced portability have been adopted. The new digital remote control unit can be operated even while wearing gloves.

* Air-cooled type

Option List

Wire feeder

Welding torch

Gas regulator

●YX-25AD1

For CO2 / MAG / MIG welding

●YX-503A

For aluminum MIG welding

Remote control unit

Connection cable

Please purchase separately as necessary.

Specifications

| Rated input voltage | V | 200 to 415 AC (200,220,380,400,415 V) |

|---|---|---|

| Number of phases | - | 3-phase |

| Rated frequency | Hz | 50 / 60 (common) |

| Rated input | kVa | 19 |

| kW | 17.5 | |

| Maximum open circuit voltage | V | 84 DC |

| Rated output current | A | 400 |

| Rated output voltage | V | 38 DC |

| Rated duty cycle | % | 40 |

| Output current adjustment range | A | 30 to 400 DC |

| Output voltage adjustment range | V | 12 to 38 DC |

| Control method | - | Inverter |

| Memory | - | 100-channel storage and reproduction |

| Sequence functions | - | Main welding / Main welding-Crater Initial welding-Main welding-Crater / Arc spot |

| Waveform control function | - | Digital setting: -99 (low) to 0 (standard) to 99 (high) |

| Applicable welding process | - | CO₂ / MAG / MIG / Pulsed MAG / Pulsed MIG |

| Applicable shielding gas | - | CO₂ : 100 % CO₂*1 MAG : 80 % Ar and 20 % CO₂ Stainless steel MIG welding : 98 % Ar and 2 % O₂ Aluminum MIG : 100 % Ar |

| Applicable wire diameter | mm | 0.8 / 0.9 / 1.0 / 1.2 / 1.4 / 1.6 (aluminum) |

| Applicable wire type | - | Mild steel (solid/FCW), stainless steel (solid/FCW)*2,aluminum(hard/soft) |

| Input power supply terminal | - | Terminal block (for 3-phase, M6 bolt fixing) |

| Output terminal | - | Dinse terminal*3 |

| External dimensions | mm | Width 306 x Depth 701 x Height 602*4 |

| Mass | kg | 55 |

*1: Ar = Argon gas, CO₂ = Carbon dioxide gas, O₂= Oxygen

*2: FCW = Flux cored wire

*3 For connection, please use the Dinse terminal (DEX SK70) that comes with the power source. Using a different terminal may cause burn damage to the one-touch joint or cable.

*4: The depth dimension does not include the input power supply terminal cover on the rear panel.

● View the required power supply capacity and cable thickness data

Support

Global Network

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website for Panasonic Shoyokai

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.

Related Links

Contact

We are here to help! Contact us if you have an inquiry or question.