Case Studies of Solving Problems

Problem: Large number of man-hours/personnel required for visual inspection

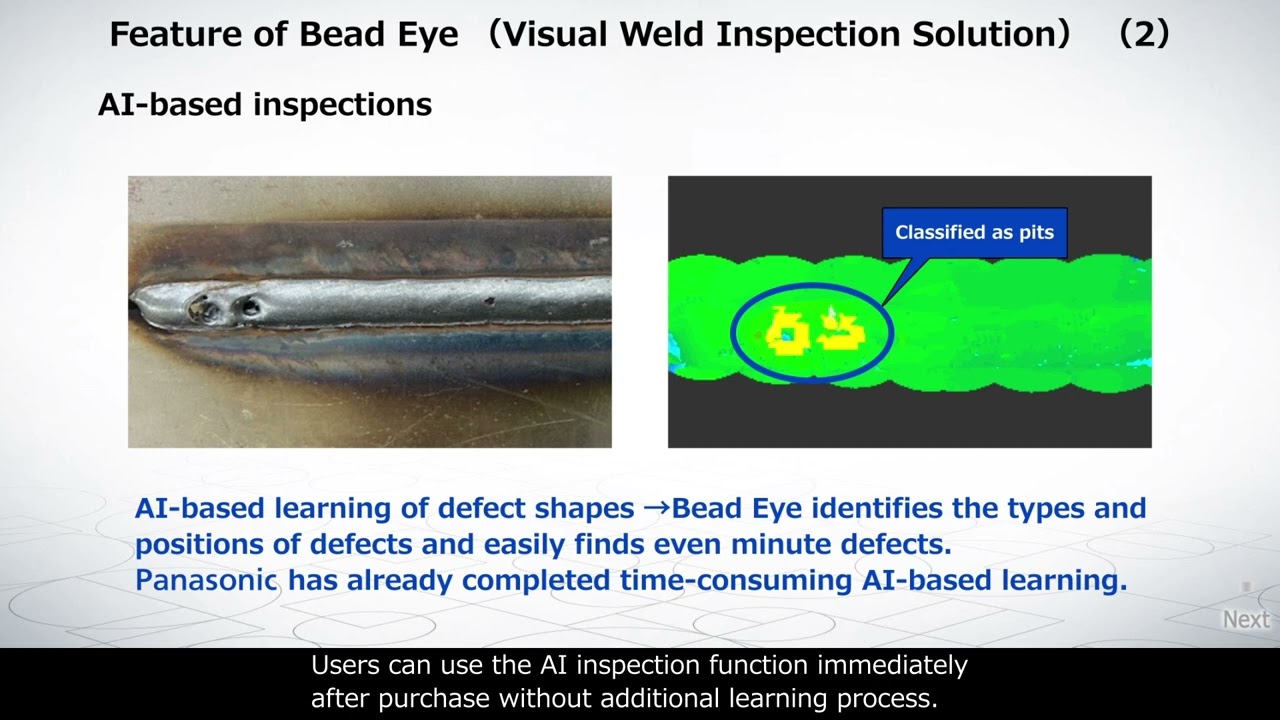

Visual inspection of weld appearance is a challenge at many worksites. This is because different inspectors have different criteria for judgment, and inspection omissions can occur. Bead Eye automates human visual inspections with a system, providing labor-saving and enhanced traceability.

Problems faced by customers

■Omissions or oversights during inspections

■Inspection criteria are ambiguous

■Difficult to secure skilled inspection personnel

Inspection process by human

Video (Inspection process by human)

Bead Eye makes it possible to automate visual inspection of weld appearance based on clear inspection criteria without omissions and oversights. A wide range of defects can be detected, including burn-through, pits, undercuts and spatter. After inspection, the inspection data can be saved on a PC that helps to enhance traceability.

Bead Eye inspection screen

Video (Bead Eye operations)

Support

GLobal network

Panasonic has established a system to support customers all over the world. Customers expanding production from Japan to overseas factories can also use our equipment with peace of mind.

Website for Panasonic Shoyokai

Website dedicated page for members of Panasonic Shoyokai. You can download the application form to join the membership website P-Web.